The Ultimate Guide to Order Processing and How to Improve It

Cyzerg

NOVEMBER 13, 2023

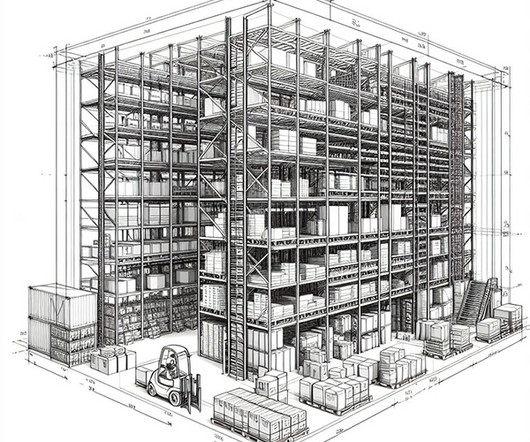

Order processing is critical to warehouse operations and is the backbone of customer satisfaction and business success. Every step is essential, from capturing incoming orders to fulfillment and delivery. We'll delve into topics such as order tracking systems, inventory management, order flow optimization, and more.

Let's personalize your content