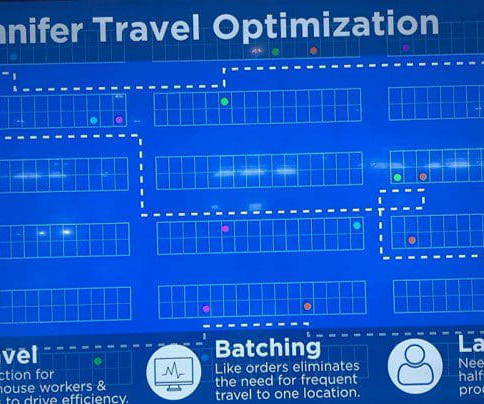

Load Building and Optimization with Tom Moore

The Logistics of Logistics

JANUARY 26, 2024

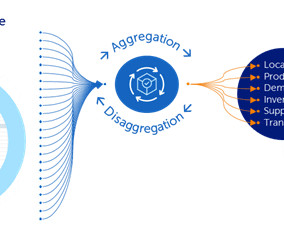

On this podcast interview, Tom Moore and Joe Lynch discuss load building and optimization. With a wealth of experience partnering with industry giants like Procter & Gamble, Unilever, Nestle, and Kimberly-Clark, Tom has been instrumental in developing cutting-edge solutions for warehousing, truck loading, and planning optimization.

Let's personalize your content