Slotting in a 3PL Warehouse

What Is Slotting?

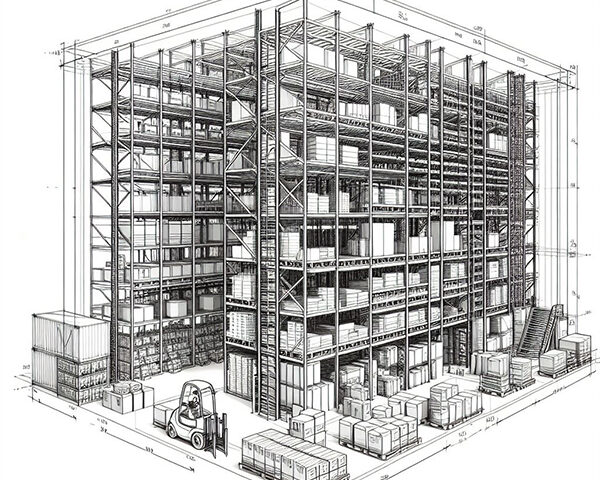

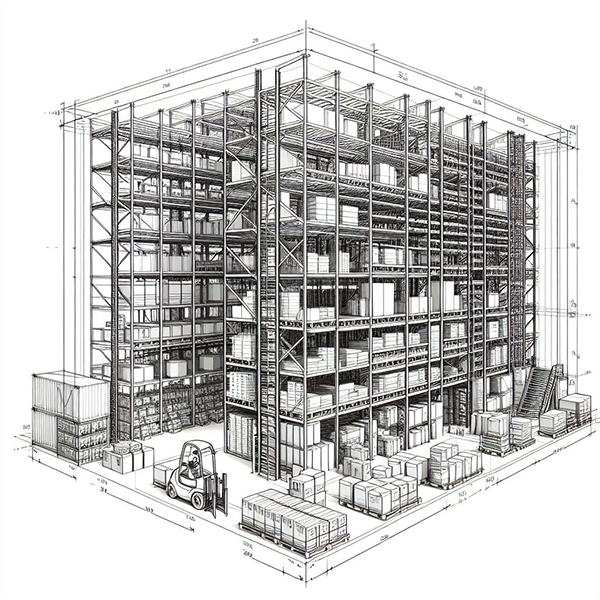

Slotting refers to the strategic arrangement and optimization of products within a warehouse. It involves determining the most efficient locations for storing items based on various factors such as product characteristics, order frequency, and picking patterns. Basically, slotting aims to enhance warehouse efficiency by minimizing travel time, improving order fulfillment, and maximizing space utilization.

Factors Influencing Slotting Decisions:

- Product Attributes:

- Weight, size, fragility, and storage requirements impact slotting decisions. For instance, heavy items should be placed closer to the ground to prevent accidents during handling.

- Order Frequency:

- Frequently picked items should be located near packing stations to reduce travel time for order pickers.

- Seasonal Demand:

- Seasonal products should be easily accessible during peak periods.

- ABC Analysis:

- Classifying products based on their contribution to revenue (A, B, or C items) helps prioritize slotting efforts.

Advantages of Effective Slotting in 3PL Warehouses:

- Enhanced Efficiency:

- Proper slotting reduces picker travel time, leading to faster order fulfillment.

- Efficient placement minimizes congestion and ensures smooth material flow.

- Optimized Space Utilization:

- Strategic slotting maximizes storage capacity, reducing the need for additional warehouse space.

- It prevents overstocking or underutilization of specific areas.

- Reduced Labor Costs:

- Less travel time means fewer labor hours spent on order picking.

- Improved organization reduces errors and rework.

- Improved Customer Satisfaction:

- Faster order processing and accurate picking enhance customer experience.

- Timely deliveries lead to satisfied clients.

- Inventory Accuracy:

- Proper slotting reduces misplacements and inventory discrepancies.

- Regular slotting reviews help maintain accurate stock records.

Challenges and Considerations:

- Dynamic Nature:

- Slotting must adapt to changing product assortments, seasonal shifts, and market trends.

- Technology Integration:

- Excalibur Warehouse management systems (WMS) plays a crucial role in effective slotting. Velocity reports are only a few clicks away!

- Real-time data and analytics aid decision-making.

- Balancing Trade-offs:

- Prioritizing efficiency while considering safety, accessibility, and storage costs requires a delicate balance.

Slotting is more than just arranging items on shelves; it’s a strategic process that optimizes warehouse performance. By embracing effective slotting practices, 3PL warehouses can elevate their operations, delight customers, and improve profitability.