How manufacturers can enable innovation on the factory floor

SYSPRO Smarter ERP

SEPTEMBER 6, 2022

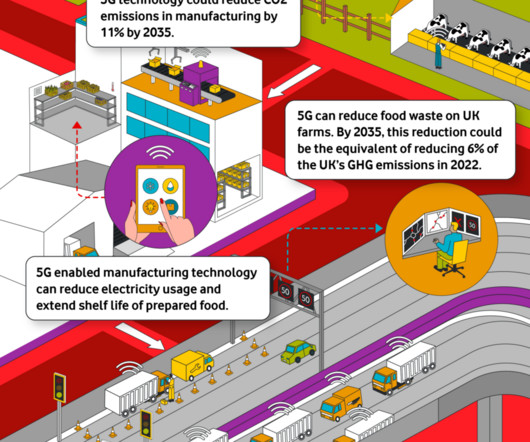

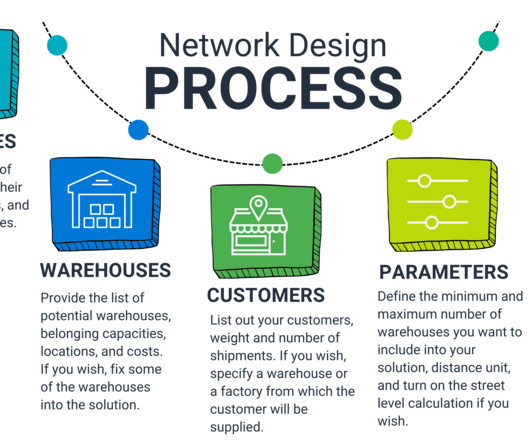

A practical way that manufacturers can do so is firstly through using data in more comprehensive ways and secondly by embracing digitization to optimize their operations for the future. Optimizing the use of data for manufacturers. Obstacles on the data journey for manufacturers.

Let's personalize your content