Introduction to Toyota Kata

The Lean Thinker

FEBRUARY 2, 2024

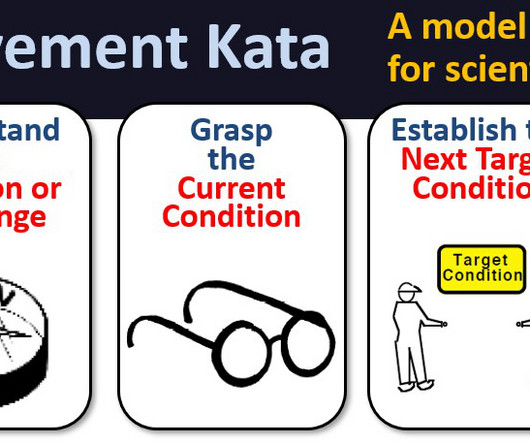

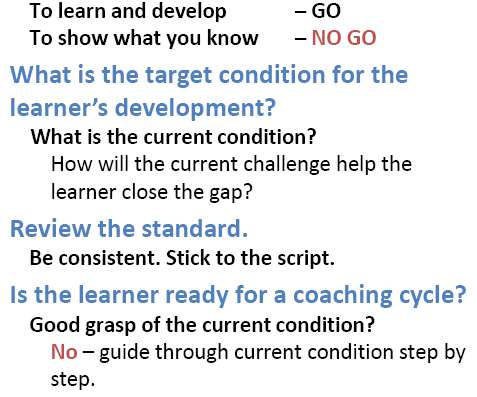

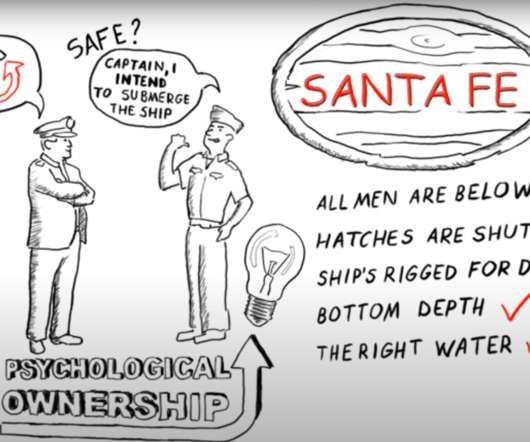

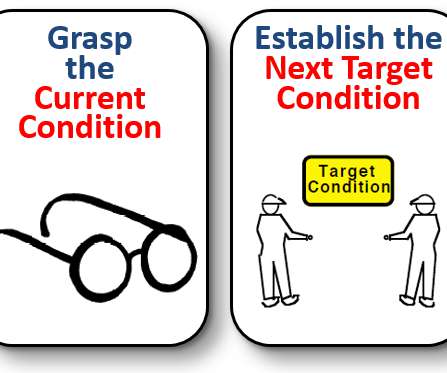

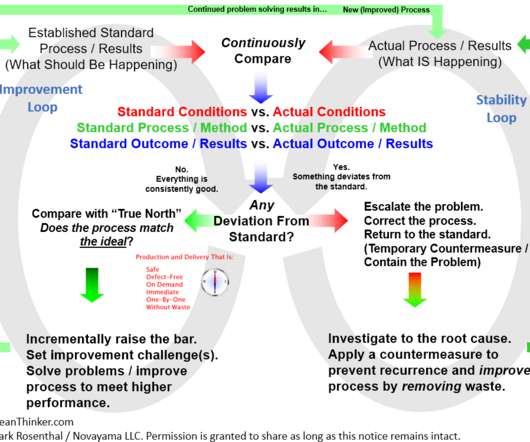

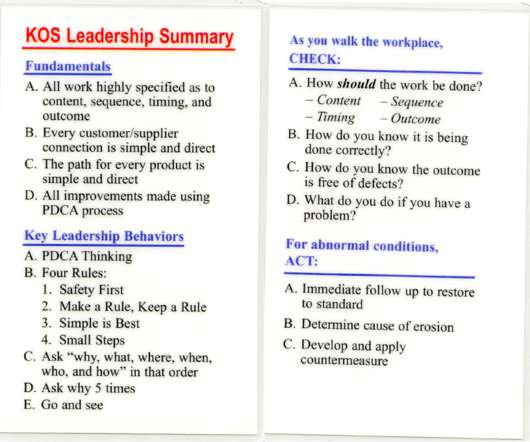

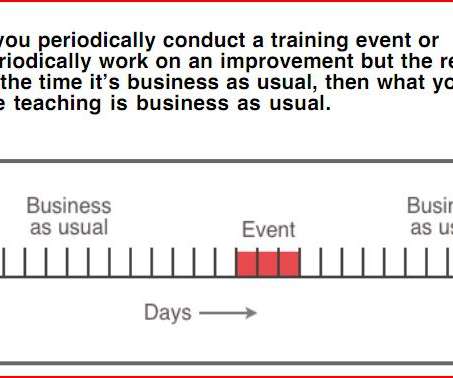

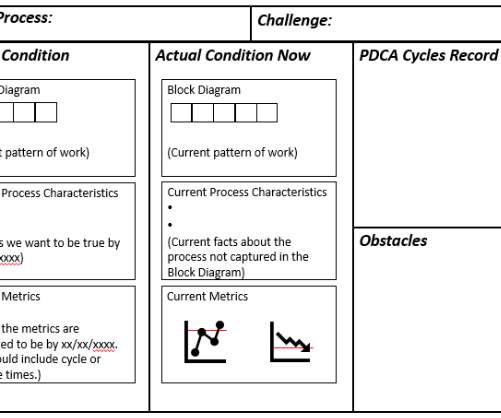

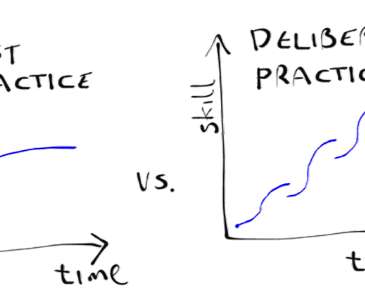

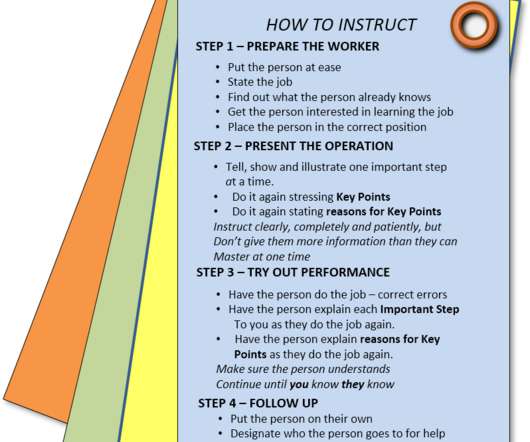

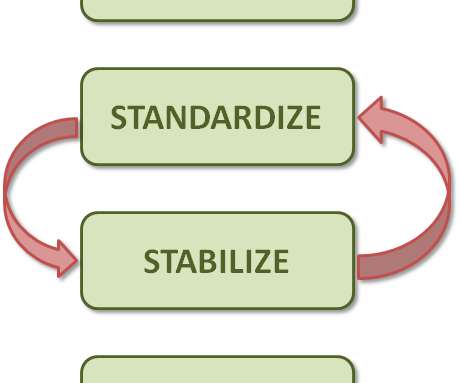

I recently did an “Introduction to Toyota Kata” session for Kata School Cascadia. The intent is to give an overview of my interpretation of the background, and how Toyota Kata fits into, and augments, your Continuous Improvement effort. Here is a direct URL in case you can’t see the embed on your phone or pad: [link] In this presentation I go over what I mean when I say “culture” and then briefly discuss a “continuous improvement culture.” Then introduce

Let's personalize your content