Inbound vs. Outbound Logistics: Understanding the Key Differences and Optimizing the Last Mile

Locus

JUNE 2, 2023

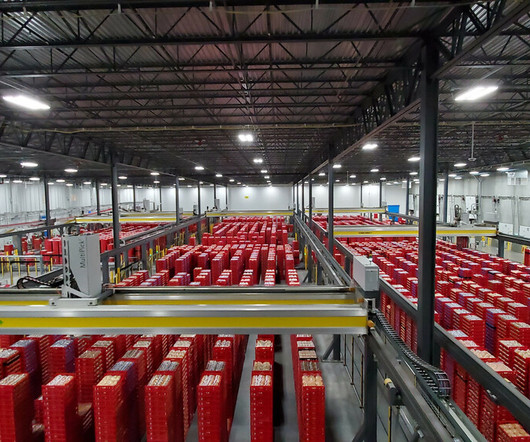

In the vast, interconnected world of supply chain management, two terms often come into focus—inbound and outbound logistics. Inbound and outbound logistics are two fundamental components of the overall supply chain management process. What is outbound logistics? Here’s an explanation of both: What is inbound logistics?

Let's personalize your content