IBP Scenario Modeling for Recovery, Restructuring and Resilience

AIMMS

NOVEMBER 9, 2020

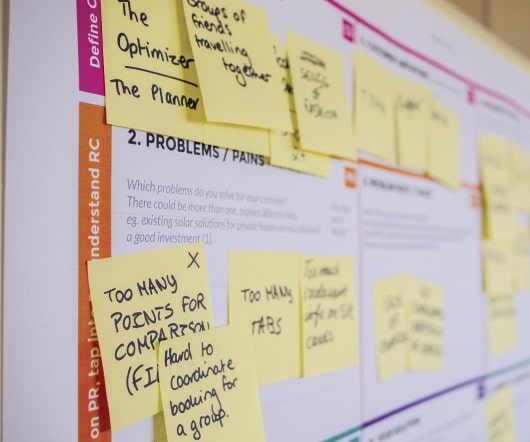

Those that also leverage scenarios in IBP are even better prepared to deal with the supply chain shocks caused by COVID-19. Our first webinar with Oliver Wight discussed common people, process and technology pitfalls that hinder IBP initiatives. Let’s explore them briefly in this blog post. Use case 2: Smart restructuring.

Let's personalize your content