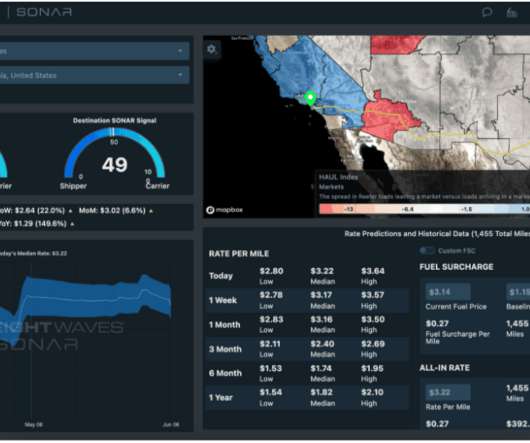

SONAR expands its reefer data

FreightWaves SONAR

MAY 19, 2021

Since its introduction in 2018, FreightWaves SONAR has provided subscribers with the most current freight market data, analysis and insights. The latest improvement to SONAR and SONAR Supply Chain Intelligence (SCI) is the addition of even more data on the temperature-controlled/refrigerated (or “reefer”) trucking sector.

Let's personalize your content