As highlighted in a June 2021 Wall Street Journal article by Bob Tita, Polaris, which manufactures boats, motorcycles, and other vehicles, is “changing its manufacturing and sales strategies on the fly to cope with shortages of materials and parts and an unreliable global transportation system that has disrupted precise production planning…The company is juggling 30 or so supply-chain constraints for its [various vehicle types] and changes its plans sometimes daily for what it produces.”

Simply put, Polaris has become more supply-driven (instead of demand-driven) when it comes to its manufacturing and sales plans. Is your company becoming more supply-driven too?

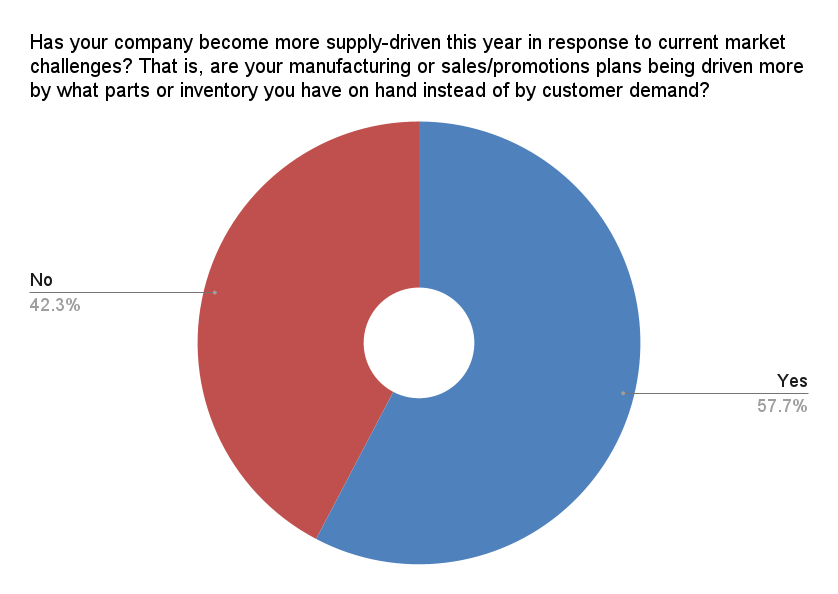

We asked members of our Indago supply chain research community that question recently and a majority of them (58%) said that they have become more supply-driven this year in response to current market challenges.

“We have faced serious supply shortages on a few products that are core to our product offering,” said one supply chain executive. “As a customer-facing, retail brand, we’ve taken steps to direct customers away from products that are in short supply (demand shaping). Many times, customers are barely aware and thankfully this strategy has been working for us without major negative impact.”

Another executive commented, “Boy, it would be nice to be supply driven for a little while. Instead, as with most times, supply chain employees are being driven to find ways to meet sales and revenue targets.”

Here are some other value-added comments from our Indago members, who are all supply chain and logistics professionals from manufacturing, retail, and distribution companies:

“Lead times have increased significantly for many input materials, which has resulted in a more dynamic production schedule.”

“Last spring, we promoted items we did not have. Now we are making sure we have product available before we promote it.”

“We have been challenged by shortages of aluminum and PET that have forced us to manage our promotions and sales differently than we have in the past.”

“We have had to make some minor adjustments to production schedules as a result of spotty global supply chains, but we have not changed from being demand-driven. Overall, we are approaching the global supply chain challenges by reviewing material sourcing and identifying secondary and tertiary sources for the material that is most impacted.”

We also asked our Indago members, “How often does your cross-functional supply chain team meet to analyze supply and demand data and refresh plans and forecasts?” The results are available to Indago members only.

Is your company becoming more supply-driven too? Are you changing your supply chain planning processes in response to current market conditions? Post a comment and share your experience and perspective!

Join Indago

If you’re a supply chain or logistics practitioner from a manufacturing, retail, or distribution company, I encourage you to learn more about Indago and join our research community. It is confidential, there is no cost to join and the time commitment is minimal (2-5 minutes per week) — plus your participation will help support charitable causes like JDRF, American Logistics Aid Network, American Cancer Society, Feeding America, and Make-A-Wish.

You can also follow us on LinkedIn to stay informed of our latest research results and news.