The concept of the Fourth Industrial Revolution (IR4.0) has been around since 2011, but it has taken time for manufacturers to understand what it means and what is needed to make it work. In the last five years, the technology to implement IR4.0 has become cost-effective and the market pressures that drive its implementation are now evident. IR4.0 can improve the way the factory shop floor works and manufacturers now have all the tools they need to operate a connected shop floor. Industrial development has transformed Asia’s manufacturing landscape. The IR4.0 will not only change the production of goods and services across Asia, but also the organization of work in factories.

What is the Fourth Industrial Revolution?

The Fourth Industrial Revolution is different from the three Industrial Revolutions that preceded it — steam and water power, electricity and assembly lines, and computerization — and refers to the merging of physical assets and digital technologies that communicate, analyze, and act upon information. This enables organizations to be more flexible and responsive and make more intelligent, data-driven decisions.

It embraces technology like the Internet of Things (IoT), artificial intelligence (AI), robots, autonomous vehicles, 3D printing, cloud computing, and advanced wireless technologies. The revolution’s speed, breadth and depth are forcing companies to rethink how they can create value. Conversely, failing to recognize and capitalize on IR4.0 opportunities will impose considerable risks

IR4.0 and the Smart Factory

The smart factory is an environment, enabled by IR4.0 digital technologies, to monitor and control the physical processes of the factory and provide data for decision-making.

Systems that support a smart factory will provide manufacturers with:

- real-time visibility into performance across the production chain, from the shop floor to the top floor;

- information to improve physical process control;

- ability to run flexible and adaptable production operations;

- connectivity between internal systems and those at suppliers and customers.

By applying IR4.0 to the manufacturing industry, smart machinery that makes use of automation and supplies real-time data for advanced analytics can help make the shop floor more efficient, create value in new and different ways, and build flexibility and resilience in a fast-changing business environment.

The Connected Shop Floor

The shop floor is central to the development of a smart factory. It is where production occurs and includes production equipment, material handling, inventory operations, operators and maintenance technicians. There are technologies available now for a connected shop floor.

- Smart industrial sensors that monitor and collect data about equipment performance, and send alerts when performance falls outside an identified acceptable range.

- Wireless communication infrastructure that supports digital communication on the shop floor between interconnected machines, parts and materials, and operators using digital reporting tools.

- Software for reporting and analyzing data coming from a variety of sources on the shop floor.

By implementing a connected shop floor, manufacturers can achieve many benefits.

- Better, faster, more cost-effective production of goods

- On-demand production changes, including small-batch production

- Customization of designs, materials, production, and delivery

- Traceability of all parts, ingredients, and materials

- Proactive, predictive maintenance through early detection of potential maintenance issues, thus reducing downtime

- Ability for operators to determine from the production schedule when equipment can be taken offline, eliminating the need for unplanned shutdowns

- Improved inventory management by monitoring the status of inventory and integration with inventory processes, enabling more effective decision-making for procurement and inventory location

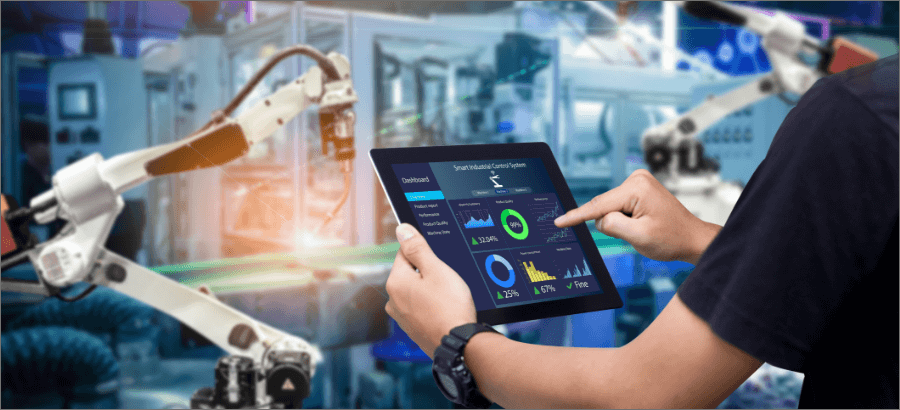

- Remote monitoring allowing operators and management to be anywhere by using mobile apps to monitor performance

How an ERP system enables a Connected Shop Floor

Manufacturers need not only digital infrastructure on the shop floor but also a system that acts as a backbone to support the Connected Shop Floor. For this, they need a manufacturing execution system (MES) that provides all the necessary functions to optimize and improve manufacturing operations — planning, scheduling, publishing, collecting, tracking, and analyzing.

As part of an integrated ERP system, shop floor data collection can collect data from connected machines and read data without manual inputs, helping to digitize the factory. It provides manufacturers with real-time shop floor visibility, while helping to eliminate manual processes and therefore increase productivity. It also enables manufacturers to monitor and execute production plans by capturing and measuring activities on the factory floor such as labor hours, materials issued, quantities reported, and scrap. This enables manufacturers to:

- drive toward world-class standards of operation for overall equipment effectiveness (OEE), total effective equipment performance (TEEP) and overall labor effectiveness (OLE);

- increase productivity and reduce costs by minimizing losses due to unscheduled equipment downtime and waste generated from inefficient processes;

- optimize operational efficiencies through improved workflow in core manufacturing activities.

The rise of the Smart Factory

Some manufacturers are beginning to understand the impact of IR4.0 and the role of technology in transforming business models and processes. The challenge is figuring out the steps to harness and realize the benefits of IR4.0. While a smart factory will not be built quickly, with the right ERP backbone manufacturers can look to create more intelligent manufacturing processes, optimizing the interaction between humans and machines to deliver a custom-built connected factory.

Industrial innovations have had a major social, economic and technological impact across Asia. Countries and industries that do not adopt technologies to automate their manufacturing operations will struggle to seize the emerging opportunities presented by IR4.0.