Forklift Telematics Data – Vital Statistics

17th May 2024

Forklift telematics systems deliver the vital statistics data that every warehouse or distribution centre manager needs to get the most from their materials handling equipment budget. But, warns Steve Ross (pictured), Operations Manager – Connectivity and Digital Products, Toyota Material Handling UK, having plenty of data is of little or no value if users have no idea what the figures mean and how to use them.

Vital statistics

Using a combination of GPS technology, sensors and the vehicle’s electric motor or ic-engine performance information, telematics systems deliver the vital statistics that every warehouse or distribution centre manager needs to understand precisely how productive and cost-efficient their materials handling equipment (MHE) is and, arguably most importantly of all, how safely it is being operated.

For example, it is generally understood that getting the best value from any material handling budget means constantly reviewing intralogistics systems to make certain that each truck is being used safely and effectively throughout every shift. Truck-connected telematics technology will flag-up any under-used vehicles within the fleet – regardless of whether a company has several hundred units or one or two machines in operation.

The data generated by telematics to highlight trucks with lower-than- expected usage rates could prompt users take the necessary action to drive down their monthly MHE running costs. For instance, trucks might be switched to other areas of the business where they can be more productive or, in some cases, equipment may even be removed from the fleet altogether if the figures fed back by the telematics system demonstrate that usage rates consistently fall below what is forecast.

But, of course, efficient forklift fleet utilisation is about more than just knowing how often a truck is used: managers need to consider how operators are performing too. For example, how busy are they during their working day? Could they be more helpful if they were reassigned to undertake alternative tasks during their shift? Are more drivers needed to run the operation smoothly or is the opposite the case? Are drivers operating the trucks safely? By tracking individual driver activity, telematics delivers the kind of actionable data that will answer these questions and plenty more.

On-site safety is another cornerstone of cost-efficient materials handling that can be improved by the data gathered by telematics systems. With losses incurred because of accidental damage to either the goods, building or the truck itself typically representing 5-15%of a forklift’s operating expenses, if on-site safety is considered in pure monetary terms alone the benefits of operating a safe site are obvious.

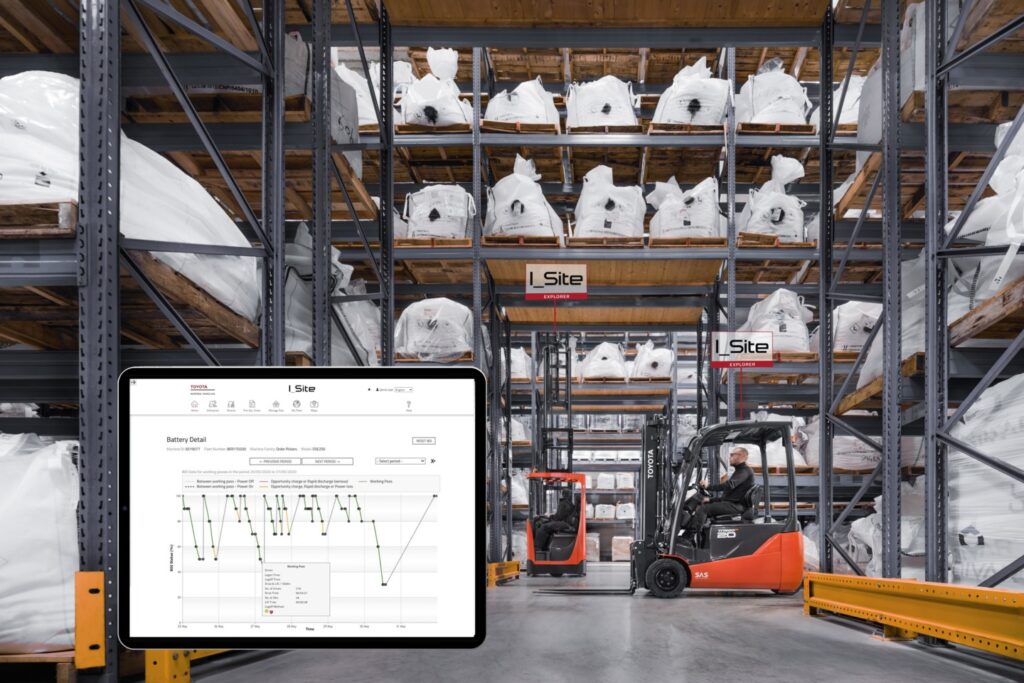

Telematics systems, such as Toyota’s I_Site, can help safety conscious companies reduce the potential for accidents in several ways. These include pinpointing precisely where forklift mishaps take place. If the data indicates that a certain location within the warehouse is something of an accident ‘black spot’, management will be alerted and, if necessary, additional safety measures can be introduced to cut the likelihood of further incidents in and around the area.

Steve Ross

Some telematics systems require each operator to use their own PIN code or smart access card to operate a truck. This feature not only restricts non-qualified personnel from operating the machinery but the fact that it makes operators accountable for their actions during a shift means that they should take far more care when going about their daily routine. Naturally, this results in a safer environment and reduced product, truck or building infrastructure damage.

A significant percentage of a company’s MHE budget can be taken up by the efficiency – or otherwise – of the battery changing and recharging process but, by using data supplied by on-truck telemetry to monitor battery and charger performance, potentially costly problems can be avoided. Failure to properly oversee the critically important recharging regime could also damage the environment and will certainly result in higher than necessary operating costs.

Companies want to collect as much data about their business processes as they can get and there is almost no limit to the type of information that can be supplied by telematics-connected trucks. But if the statistics can’t be harnessed because they are presented in a way that only a professional data scientist could understand they will be of little or no value. In fact, having plenty of data can become more of a liability than an asset if users feel overwhelmed by it or have no idea how to use the figures in ways that will benefit their company. And, if that happens, the data tends to be left to gather dust!

Toyota is a market leader in telematics and introduced its I_Site MHE telematics technology more than 20 years ago. From the outset, I_Site has been designed to deliver valuable business insights, rather than simply supply users with figures and statistics. The system gives logistics professionals knowledge that they can use for the benefit of their businesses by presenting data as meaningful, helpful and actionable Information.

But by presenting a crystal-clear overview of everything users need to measure, analyse and improve their material handling operation I_Site allows logistics managers to take the sometimes-difficult decisions that are needed to keep full control of the intralogistics processes that they oversee. And by doing so, their companies will experience the true value of telematics.

read more