5 Powerful Prescriptive Analytics Examples in Supply Chain

Prescriptive analytics is a type of advanced analytics that optimizes decision-making by providing a recommended action. This type of analytics is used across industries to answer complex planning questions. In fact, the electricity that powers the computer you’re reading this on is probably dispatched using prescriptive analytics models. Prescriptive analytics is also frequently used in another industry that touches many aspects of our lives: global supply chains.

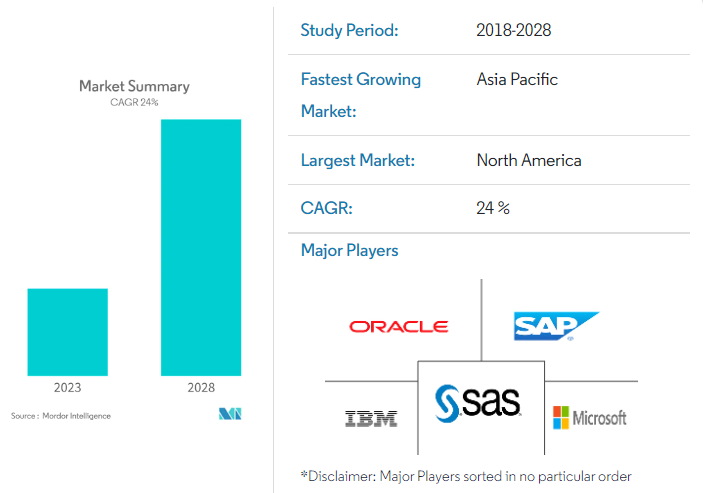

According to Mordor Intelligence, the predictive and prescriptive analytics market will grow with a CAGR of 24% over the forecast period (2023 – 2028) and North America will be the largest market.

In this blog, we will explore 5 powerful prescriptive analytics examples in the supply chain.

1. Supply Chain Network Design

Supply chain network design is a strategic supply chain planning activity that focuses on two things:

- Determining your supply chain’s footprint: where to place facilities and how big they should be.

- Determining how products should flow through the supply chain.

The supply chain network’s design will determine the capacity of the business facilities, and the movement of raw materials, intermediates, and finished goods – from the source to the point of consumption. Decision-makers must consider many complex variables in their network design choices, including the cost of labor, customer locations, and available transportation networks. Because of the sheer size and complexity of today’s supply chain networks, these decisions are typically supported by prescriptive analytics.

Network design solutions often have optimization solvers in the back-end that can take the business’ complex constraints into account to deliver an optimal answer. AIMMS Network Design is an example. The application is fueled by powerful mathematical optimization in the back end, and intuitive scenario analysis capabilities in the front end, empowering you to create optimal designs and expose hidden risks in your network.

There are many benefits organizations can gain by applying prescriptive analytics for supply chain network design. Most notably:

- Compelling cost savings. Total cost savings can be up to 30% in some cases, depending on the size of the company.

- What-if capabilities. Create scenarios to analyze all possible situations and be ready for unpredictable circumstances.

- Improved resilience and agility. The ability to base decisions on data with clear visibility of the trade-offs helps leaders make critical decisions faster and in an informed way.

- Improved service levels. With a better understanding of your network costs, you can make better decisions about your DC locations, prioritize the right customer segments, analyze your cost to serve and improve service accordingly.

2. Sales & Operations Planning/ Integrated Business Planning

Sales and operations planning (S&OP) is an integrated business management (IBP) process that seeks to align supply and demand. Although it is often led by supply chain teams, it seeks to drive focus, alignment, and synchronization among all functions of the organization. The S&OP process typically starts with the forecast. It results in sales, production, inventory, and new product development plans, as well as a financial plan. Integrated business planning is the evolution of S&OP.

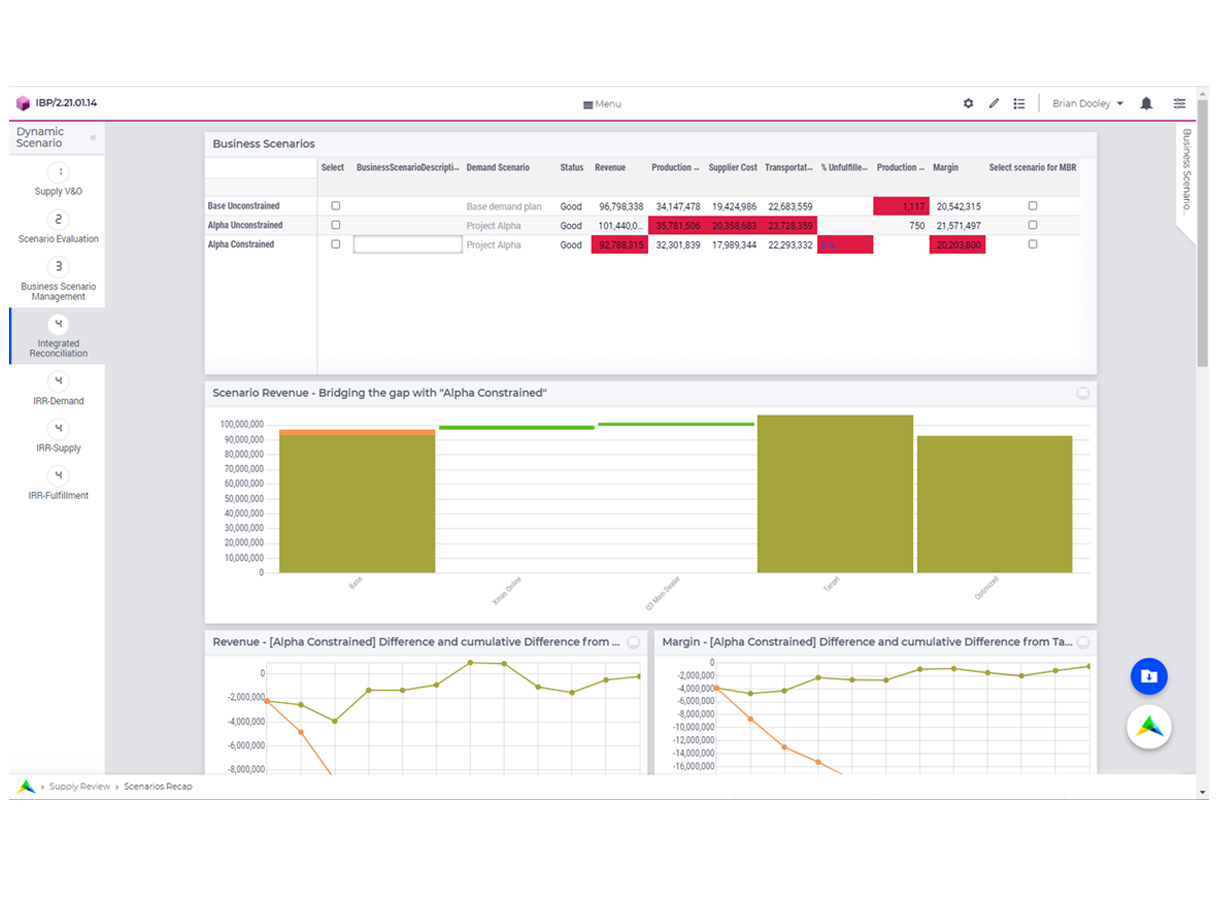

Both processes can benefit greatly from prescriptive analytics, as the decisions they drive entail many complex constraints and large amounts of data. Scenario modeling is also a best practice in S&OP to evaluate opportunities and KPI trade-offs.

Some of the benefits organizations can gain by using prescriptive analytics in this area include:

- Improved communication and alignment. Being able to look at scenarios and KPI trade-offs side-by-side helps to assess different courses of action and get buy-in.

- Between 10-40% improvement in on-time product delivery.

- Lower costs on the transport side.

- Up to 70% lower inventory levels.

- Plant efficiency improvements of up to 30%.

3. Sales & Operations Execution

Sales and Operations Execution (S&OE) and Sales and Operations Planning are often mixed up. But while the scope of S&OP might be monthly or quarterly, the scope of S&OE can be weekly or even daily. S&OE can be seen as a subset of S&OP.

As Gartner explains: “a good way to think about S&OE is to picture a middleman that receives, interprets and forwards information between the operational and strategic levels. It breaks down the strategic input from S&OP into detailed instructions that can be executed.”

According to our research, S&OE is growing in importance across industries. This is largely due to increasing demand volatility and uncertainty. Companies must do more “firefighting” to adapt and meet customer service requirements.

Almost 40% of companies use Excel for S&OE and related incident management. But a lot of data and variables go into the S&OE process. Using Excel can mean aggregating decisions at higher levels and potentially missing out on savings.

Planners typically want to consider inventory usage and allocation, production scheduling, and supply strategies. Customer prioritization is often included in the process too. With so many things to keep on the radar, it can be difficult to focus on improvements.

Prescriptive analytics can help teams untangle a lot of this complexity and collaborate better using available data. Optimization models help teams select the right action when the unexpected occurs and get insight into how their decisions impact products and customers. Combining optimization with scenario modeling also helps teams assess performance in times of crisis and model alternative ways to solve issues as they arise.

How teams benefit:

- More resilient planning decisions

- Improved ability to deal with the unexpected

- Increased customer satisfaction

4. Inventory Optimization

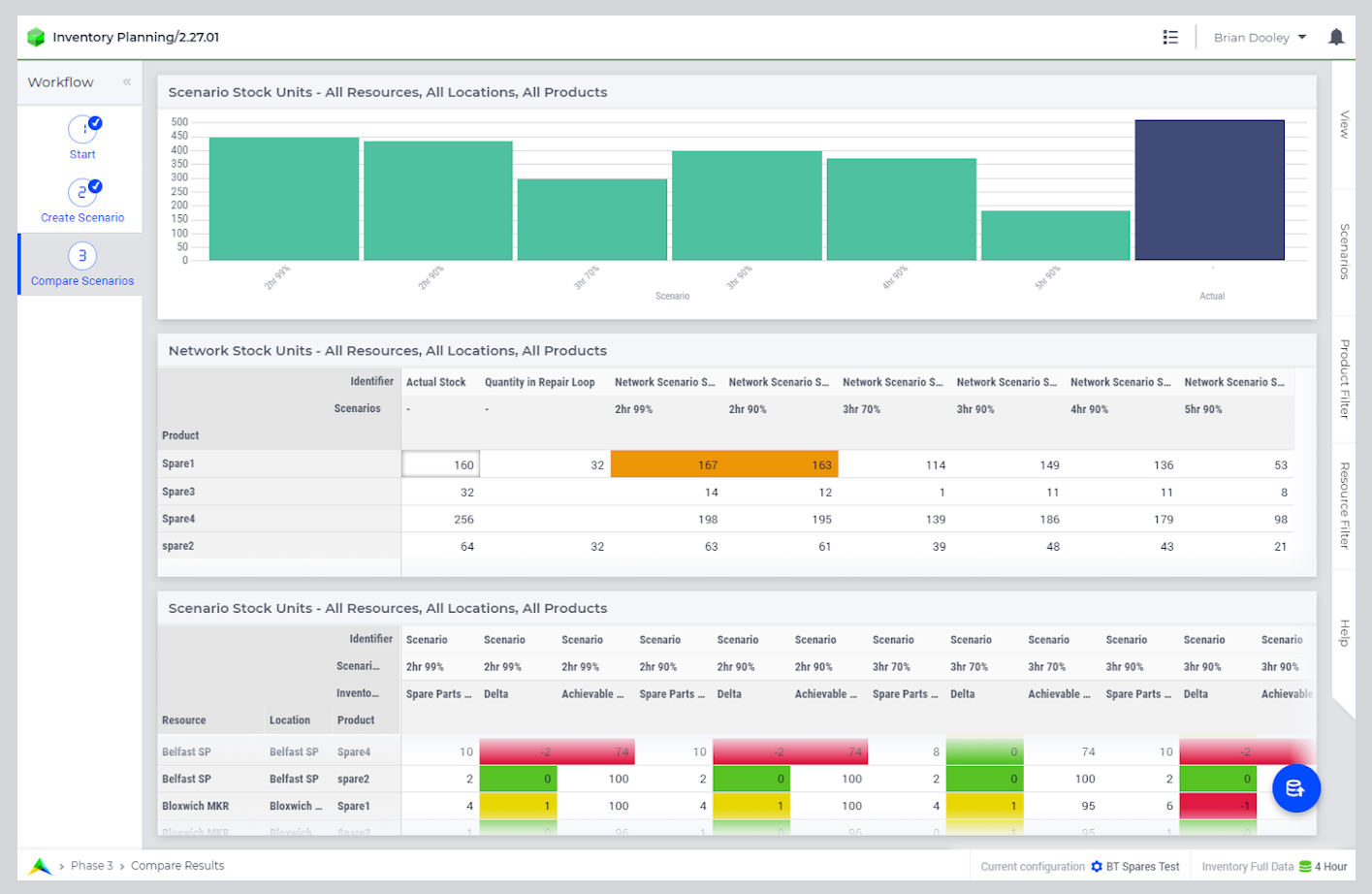

Inventory optimization is another area where prescriptive analytics is commonly used. Inventory optimization is the process of setting inventory levels to balance demand and supply uncertainty while maximizing customer service and minimizing costs.

On the surface, inventory calculations seem reasonably straightforward. Yet, they do require lots of data to be effective. Companies consider many inputs when calculating inventory levels, including demand variability, the forecast, lead time variability, service levels and more.

While most companies use spreadsheets for inventory optimization, most are not satisfied with this tool. Managing this data in an environment that allows you to easily model different inventory policies and their impact requires a specialized optimization solution. Scenarios are a great way to engage stakeholders outside of the supply chain and show them the inventory consequences of different business choices as well.

Using prescriptive analytics and scenario modeling typically yields the following benefits:

- A 20% reduction in out-of-stock occurrences (or more)

- Reducing inventory and potential service risks

- Lower costs

- Planning efficiency

5. Warehouse Optimization

Running a warehouse is a highly complex process. Last-minute changes and intricate processes make this an area that is especially suited for prescriptive analytics tools like mathematical optimization.

Companies have been using mathematical optimization in warehouses for some time. Typically, they do so to:

- Determine the optimal location for certain products.

- Determine optimal inventory levels.

- Determine the optimal stacking configuration for pallets. Mathematical models are sometimes used in combination with automated palletizing systems to achieve this.

- Optimize schedules for warehouse employees.

- Optimize order picking activities and picking path length.

Some of the benefits they gain include:

- Increases of 15% or more in warehouse capacity

- 10% or more in productivity improvements

- Streamlined fulfillment operations

Ready to optimize your supply chain with prescriptive analytics?

Explore other use cases in supply chain to get inspired. Contact us to learn more about using AIMMS to optimize the many aspects of your supply chain.

Is this a SaaS, Service? Is the tool on prim or in your cloud? Is this subscription or license?

Hi Barbara, we are a SaaS company that can be on cloud with any of our subscriptions.