Why is freight data a powerful weapon in the era of COVID-19?

FreightWaves SONAR

SEPTEMBER 29, 2023

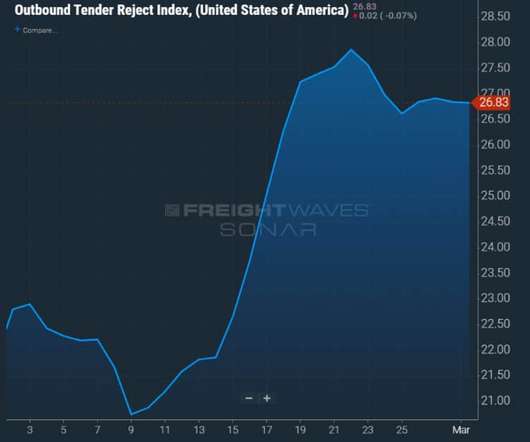

HOW MUCH DO PAPER AND PACKAGING COMPANIES SPEND ON TRANSPORTATION? Download the White Paper FREIGHT DATA KEEPS EVERYONE INFORMED Miscommunication was a major issue during the first months of the COVID-19 pandemic. Using data, supply chains could better plan replenishment orders, avoid congestion and prevent further disruption.

Let's personalize your content