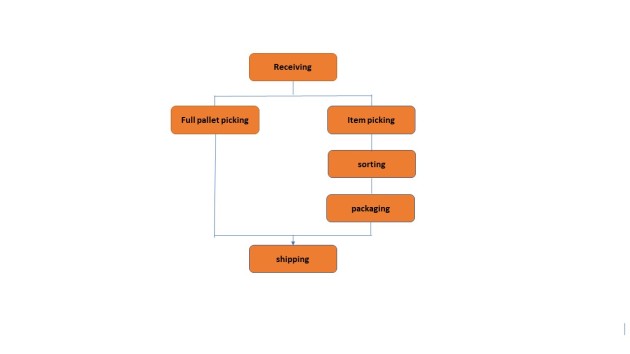

First, I would start to define the Order picking operations:

In the last class, we were talking about the picking order systems such as pick to light and voice picking I would like to mention the pick to light automotive system uses in most of the companies especially big companies.

The benefit of paperless is to increase the productivity, near 100% accuracy, labor optimization, real-time data available, and the elimination of redundant tasks (paper list, order checking), in addition to Rapid training hours, not weeks.

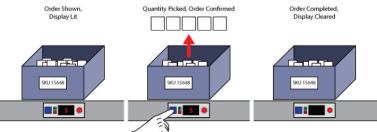

Pick to light system:

The pick to light system is simple, each pick location on a flow rack, shelving unit and pallet rack or other storing location system. is mounted with a light display module to indicate the number of units to be picked whenever the product is needed from a location .as each item is picked, it can be confirmed as complete or marked as incomplete notifying the host server of a stock out condition. The order is automatically updated with what has been picked fully and what must be back ordered, the instant feedback from pick to light can drive real-time inventory systems and this information can be used to automatically drive stock replenishment to the picking area as minimum stock levels are reached.

The companies install pick to light system when they want an accurate and fast picking to be performed. I saw an excellent example of this system in Saramax Apparel Group they manufacture clothing garments. The company offers loungewear, sleepwear, infant layettes, undergarments, and kids apparel, they are a fully functioning warehouse, shipping, receiving, they use the production area to package and repackaging. They were facing many problems in the picking area and they use the Pick to light system; the new system provides Saramax with all the pick location required The solution has increased operational efficiency, added capacity, performance, visibility, and control, for example, the system shows how many pieces should the operator takes, and when the operators press the button then he/she finish picking. after picking.

Once the person is trained to use the system, usually in less than half an hour, individual picking productivity and accuracy is improved sustainability over that found in traditional paper-based operations.

source: