Before telling you a story about Toyota and Formula 1, let me begin by explaining what is the SMED.

SMED stands for Single Minute Exchange of Die. This method is used in the Just-In-Time strategy, which is a method related to inventory where materials are only ordered and received when they are needed. The goal of Just-In-Time is to decrease waste and increase the efficiency of the inventory process. Keep reading until the end, I promise the fun story will come soon!

The aim of the SMED is to reduce the time it takes to produce some parts of the product, to reduce the overall cost of making a product or delivering a service and to increase the flexibility in the production process.

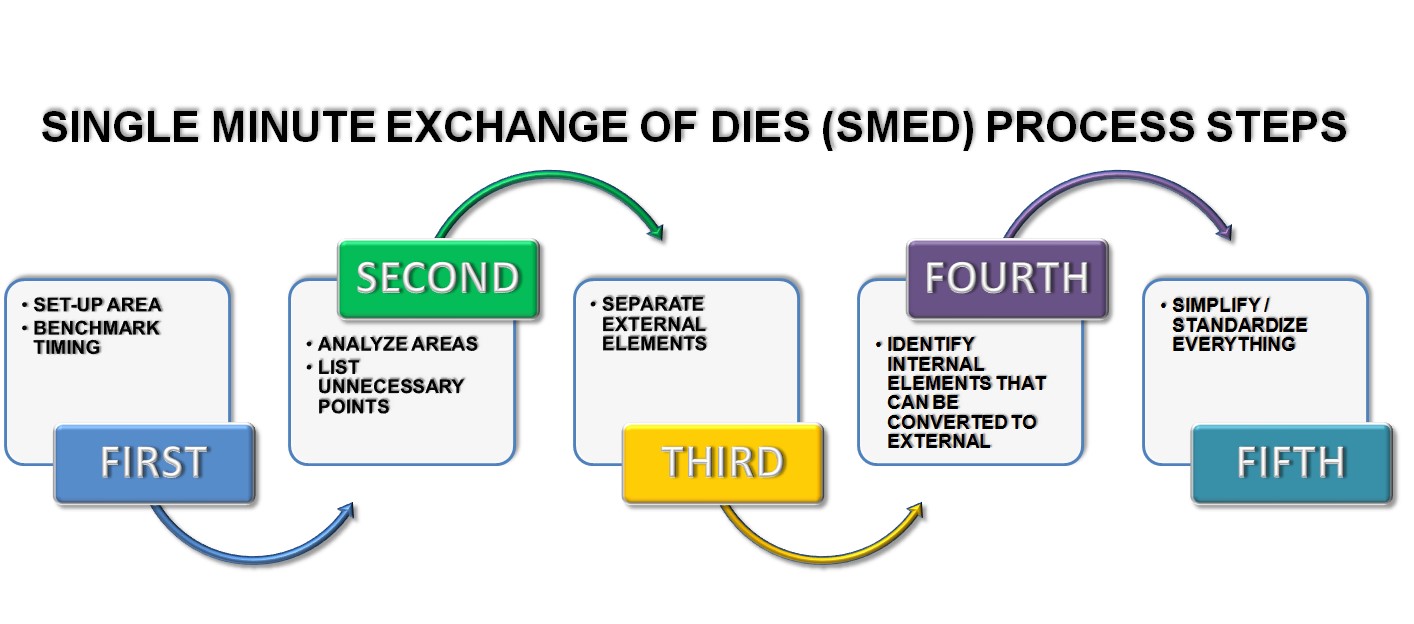

The way to implement the method is the following one:

If the concept of Single Minute Exchange of Die remains unclear, you can check this 1min video. 🙂

Now, let’s talk about Toyota and Formula 1. Toyota is actually one of the first company who began using this method. It was created by Dr. Shigeo Shingo, who was an industrial engineer from Japan.

They began using it as when they were trying to improve the time it was taking to change the tires of the car during races. In 1950, it was taking one whole minute (which can strongly impact the race!) to change the tires. Today, it only takes..2 seconds! Watch this video if you want to see how SMED can make major improvements in terms of efficiency and reduction of “waste”! 🙂

Sources: https://www.sixsigmadaily.com/single-minute-exchange-of-die-smed-definition-example/ & https://www.processexcellencenetwork.com/business-process-management-bpm/articles/single-minute-exchange-of-dies-smed