In the last lecture about warehousing, our Logistics Professor mentioned the company “Kiva Systems”. I found it very interesting that amazon bought this start up for $775 million in 2012. I was wondering why amazon would spend that much money for a warehousing system which by the way was amazon´s second largest acquisition at that time. So it did more research on it.

How does the system work?

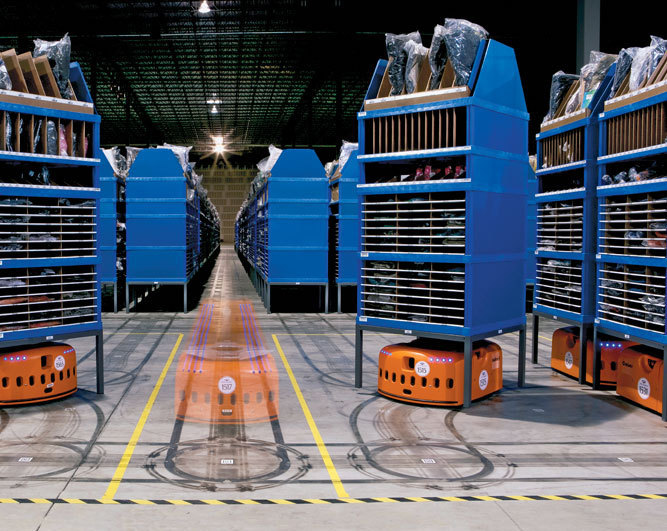

Traditionally, goods are moved around in a warehouse using conveyors or forklifts which is called “operator to product approach”. With Kiva´s approach, items are kept on portable storage units and automated guided vehicles move the storage units to picking stations where the pack worker picks the items of the storage (“product to operator approach”). The software coordinates the robots and allows wifi communication for path planning and route management. The robots move around the warehouse orientating themselves on many 2D barcode stickers on the floor. Sensors prevent the collision of robots.

The following video shows how amazon uses the system.

History

Kiva Systems” is a US start up that was founded in 2003 by Mick Mountz and Pete Wurman. By fundraising the company got over $18 million of capital until 2006. Follow this link for details on the fundraising. The company was very successful and by 2012, its revenues passed $100 million and the company hat 240 employees. In the same year – as mentioned above – amazon bought “Kiva Systems” for $775 million dollars which was its second largest acquisition at this time. Since then, Kiva Systems has stopped its marketing activities, as amazon is using it exclusevily for their warehouses.

What are the robots doing?

- Customer submits order and order gets into database.

- System identifies target storage units where items are located.

- System selects the closest free bot and sends the direction of target storage unit.

- Bot drives to target storage unit by tunneling the storage units (driving underneath them) leaving the highways free for inventory traffic.

- Bot lifts the storage unit with a cork screw motion some centimeters from the ground so it can be carried.

- Bot drives on small streets to the highway on the side of the building.

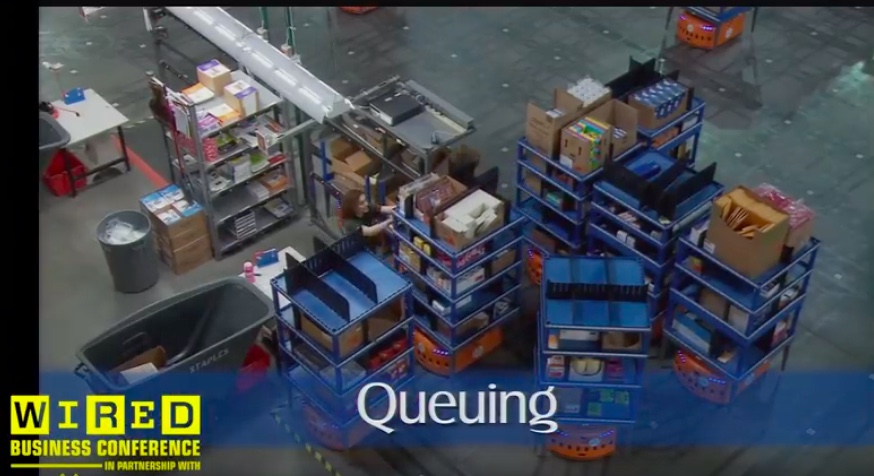

- Bot drives on the highway until the queue at the picking stations.

- Bot returns the storage unit to a free place in the warehouse depending on what is left on it and dropped it.

- If necessary, bot drives to the charging station.

See pictures of the different steps by clicking through the gallery and watch this 3 minutes video where the founder explains the “working day” of a robot.

What are the advantages?

Quantity of orders:

The “Kiva System”can handle “two-to-four times as many orders per hour as they have done the old way” (dispatching workers to find products). This link leads you to a video on a test of the speed of the system at minute 4:51.

Benefits for workers:

Workers have constantly tasks to do and do not have to wait. The system is ergonomically, and workers do not have to walk in the warehouse. The training circle time for new employees can be reduced to less than half a day. To see how a worker picks the items, see the video above at minute 1:34.

Safety, security and inventory accuracy:

As no humans have to move in the storage, the rates of accidents are very low. The security of goods in the warehouse is higher, as no humans are there. The rate of inventory accuracy is at almost 100% as human mistakes are avoided.

Energy savings:

As no workers are in the storage area, light and climate does not need to be adapted to humans what saves energy.

Moving the whole system on a weekend:

In contrast to “old-fashioned” warehouse, the whole “Kiva System” can easily move to another warehouse over one weekend if the old warehouse gets to small.

Customer service:

The customer service increases as the delivery time decreases as the picking can be done much faster.

If you are interested on the advantages, in the following video a company explains how the implemented the Kiva system and how the profited from it.

Hello!!!

I liked so much your post, I’ve found a video related with the warehousing.

I hope you like it 😀