Following the same structure, after answering the possible exam questions I have found really interesting some of them and I would like to talk about another one as my previous post.

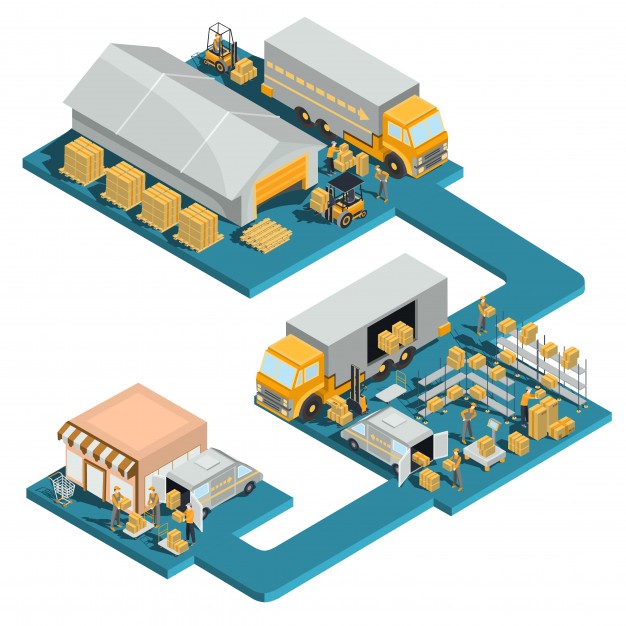

This question is related with the main processes that occurs in the warehouses, processes which involves all the different tasks needed to develop a product.

There is a plenty of variances in how each process is physically conducted and electronically controlled depending on the company. Which are these processes?

1. Receiving

The act of handling products into a warehouse and onto a system. This depends entirely on the customer requirements and how the system is set up.

2. Put-Away

A good system will deliver to the staff a note indicating that stock is in staging waiting to be transported to a storage location.

3. Picking

Although there are several types of picking, they can be divided into to main types:

- Primary, the picking of goods

- Secondary, this is a second picking process related with already sectioned goods by groups or even individual

Once orders are received they can be released in real-time or in waves:

- Real time downloaded as they are received

- Waves orders accumulated for specific picking times

- Packing

There are scores of ways that goods are packed within distribution centers, according the value, toxicity, hygiene, temperature, size.

4. Dispatching

Focused in the operation’s ability to have goods ready for departure, just in time for carriers to load their trucks.

5. Returns

Complex part of any business. Returns is a complex part of any business. A defined process must be in place that accurately and reliably records the whole transaction and credit process.

6. Value-Adding

This part is about performing work on the product to make it ready for sale.

Warehouse management is complex, but done right it can reduce costs, improve customer satisfaction and increase warehouse operational efficiency