Today I want to present to you the topic of digital twin for warehouse and distribution centers.

The goal is to get an insight, how it could be implemented and in which way that technology operates. I found a german startup company that present that topic really lively and shows in a graphical way how it could improve the daily business.

If you want to learn more about the company “Logivations – Consulting & Technology” click here.

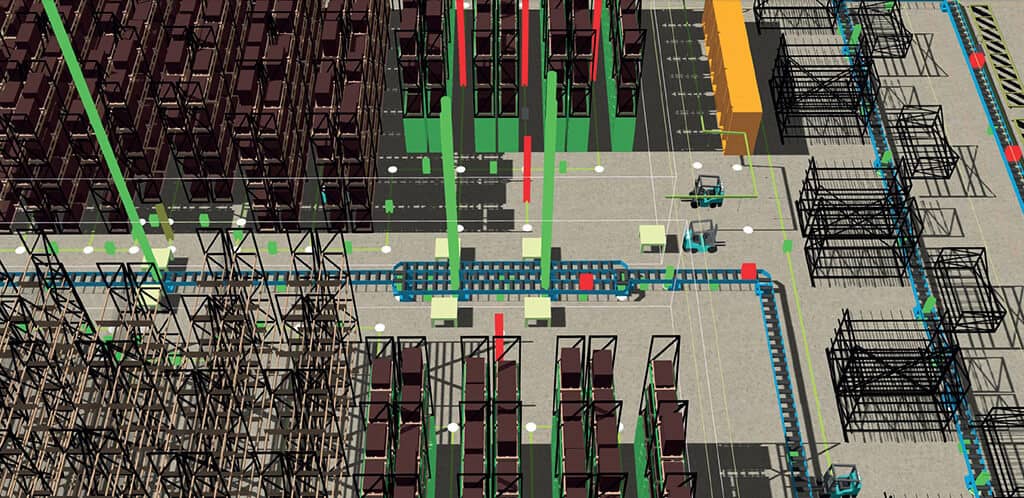

Logivations uses a combination of a 3D model and feeds it with current live data. This data includes tracking, throughput or inventory of individual products or materials. Furthermore, they simulate the material flow, staff deployment and the use of forklift trucks.

According to the implemented data, the company is now able to identify unproductive processes and eliminate them. Below you will see a picture how a digital warehouse could look like:

Packing Process

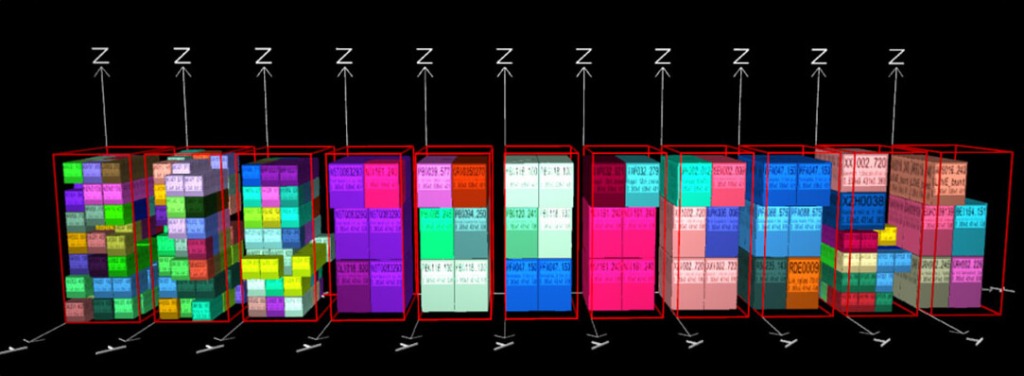

Not only the pick-up time and the placement of the products can be optimized, also the packing process itself can be revolutionized. Choosing the correct transport container can significantly increase or decrease your transport costs. A twin tool can help you to identify the correct transport method and how to transport them in the safest and most cost-effective way.

A 3D-package builder is able to choose the correct transport container considering all relevant figures such as product dimensions, outer packaging, material flow and joint packaging restrictions. The results can you see below and can be directly depicted to the workstation over tablet or monitor. Therefore, the employees will get a guideline in order to help them to increase their efficiency.

However, the digital twin technology is not only useful for current products that need to be packaged, it can also be helpful for new products. Once you put in the data of a new customer order, you can calculate precisely how much it will cost and what storage or transport facilities are needed to fulfil that order. You will be able to determine whether it is beneficial for your company to accept that order or if the customer wish is simply not profitable for you.

In conclusion, the digital twin technology can support the whole business organisation – starting from manufacturing until the customer received the order. The importance of that technology will tremendously increase in the next few years and enable the fact to simulate even unpredictable scenarios, like we currently see in the worldwide corona crisis.

If you want to learn more about that topic, “Logivations” offers a free webinar about optimized picking tours. It is held in English and on 6th of April.