The exponential impact of e-commerce on traditional, brick-and-mortar retailers, is one good example of how the data-driven revolution is sweeping many sectors of the economy and business operations nowadays.

Few organizations have been able to apply the “big analytics” methods that are revolutionizing the ways to define and organize the supply chain operations. Two major challenges might be limiting big data to fully impacting the supply chain. First, there is a lack of capabilities: even supply chain managers with advanced technical skills, fall way behind in the experience with data analysis techniques. This results in a lack of vision to see what big data might be capable of in the industry. The second challenge is that most businesses do not have structured processes for exploring, evaluating, and capturing big data opportunities in their supply chains.

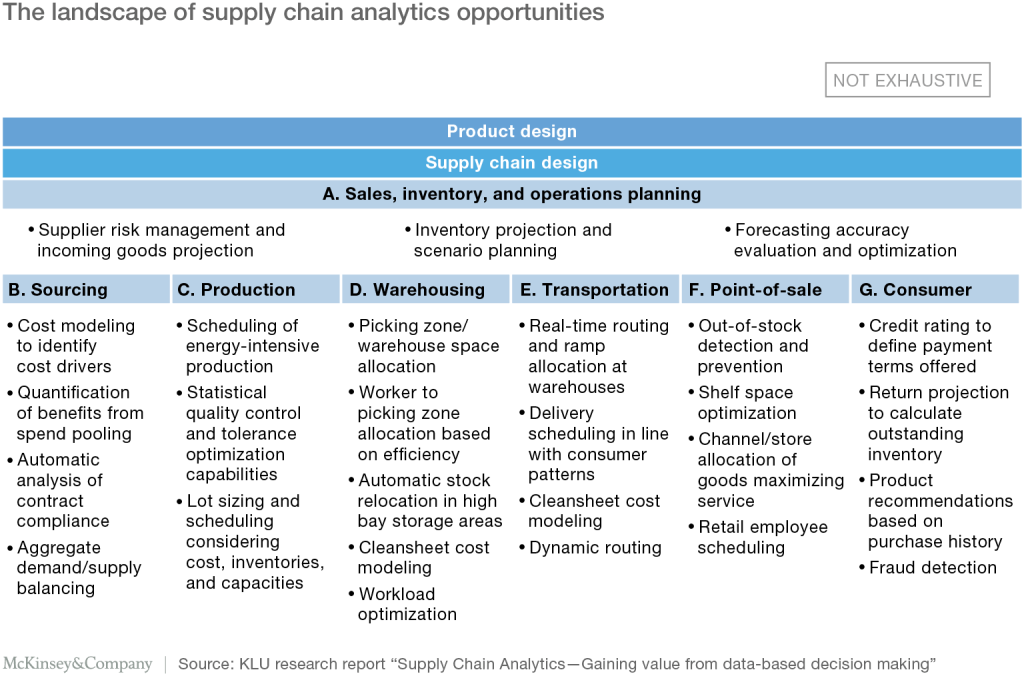

Opportunities in supply chain areas with the use of Big Data.

For a more in-depth analysis about the opportunities in the supply chain industry driven by applying Big Data: https://www.mckinsey.com/business-functions/operations/our-insights/big-data-and-the-supply-chain-the-big-supply-chain-analytics-landscape-part-1

UPS success case

Companies can now optimize deliveries regardless of the obstacles they might find in the road thanks to GPS and location sensors, as well as real-time traffic reports, that allow them to change their path in real time. UPS could be the most successful big data story in the logistics industry. The company has made significant progress in efficiency improvements and lowering costs through collecting and analysis of data, planning, and forecasting.

More than 200 onboard sensors in 80,000 vehicles measure variables such as speed, location, and idle time. Some of the sensors collect also data on the vehicle’s battery and tire pressure, creating opportunities for proactive maintenance, which is always more efficient than reactive. The goal is to keep a vehicle on the road as much as possible rather than in the shop. Big-data-driven predictive modeling serves as the catalyst for route optimization.

UPS used big data to cut fuel consumption by an estimated 1.5 million gallons in 2012, significantly reducing emissions while increasing operation margins through efficiency. Also, related to cutting costs, they managed to reduce the wear and tear on vehicles through route optimization. This route optimization models also provide truck drivers with an innovative and unusual solution: they never turn left. When the optimal paths are traced, only right-turn directions are included, reducing the vehicles’ idle time at red lights.

While some firms are starting to invest in greener technology as well as big data initiatives, many supply chain companies are developing new techniques that imitate the outcomes of route optimization by trying to master inventory logistics management and optimizing shipments for efficiency.