The COVID-19 crisis unveiled major issues within global supply chains and, as we have seen with SONAR freight data, volatility in the market. As core sections of economies around the globe shut down, manufacturers and vendors found themselves in a precarious position. A lack of raw materials and products from suppliers created supply chain disruptions. These occurred in conjunction with unprecedented demands on existing supply chains, particularly those involved in hygiene, cleaning goods and household essentials. However, the solution to the supply chain issues and disruptions is much simpler than most companies realize. For those that make the right applications of freight data, the massive problems created by the pandemic could have been more easily mitigated. In fact, more air capacity is already lowering the pressures on shipping rates. How? Let’s take a closer look at how freight data is the most powerful weapon against any form of supply chain disruption.

HOW MUCH DO PAPER AND PACKAGING COMPANIES SPEND ON TRANSPORTATION?

FREIGHT DATA KEEPS EVERYONE INFORMED

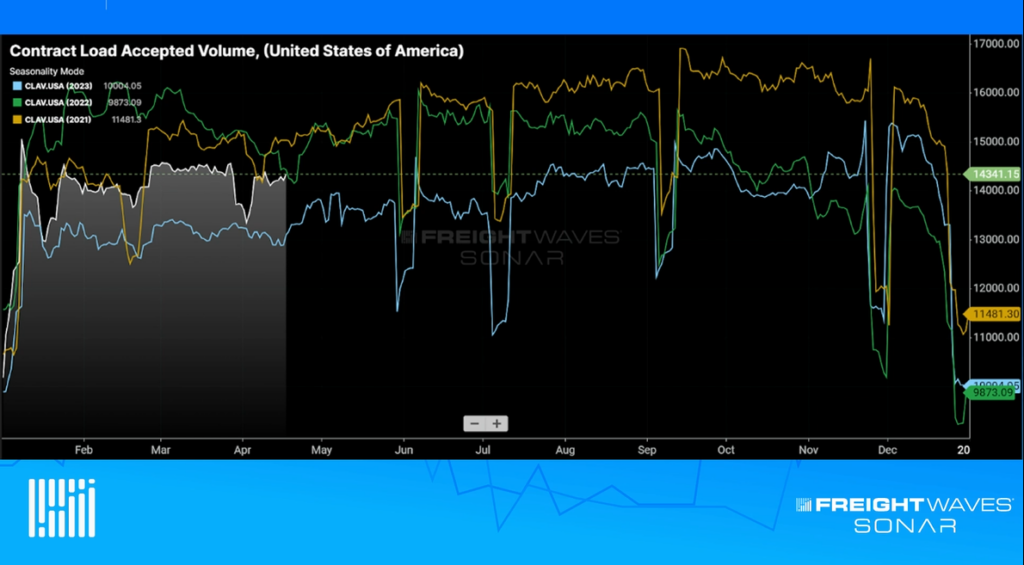

Miscommunication was a major issue during the first months of the COVID-19 pandemic. As companies tried to keep responses to COVID-19 under wraps, problems quickly spiraled out of control. Unfortunately, keeping everything hush-hush in the freight world is an absolute disaster. It sets an organization up for failure, and it causes organizations to lose rapport with other parts of an existing supply chain. Quite simply, the variety and complexity of supply chains often contributed to a breakdown in communications between members of supply chains as the pandemic continued. This also served to lead to poor or lost collaboration. As reported by McKinsey & Company: “The degree to which each mode of transport and trade lane is affected depends on their particular commodity mix. When planning for the future, industry players should thus use insights from commodity-based modeling. For example, as seen in scenario A1, the global unconstrained demand for air cargo will fall by 14% of pre-crisis volumes in the second quarter of 2020 and will not rebound to 2019 levels until around mid-2022.” Now, consider what might’ve happened during the first weeks and months of the pandemic had organizations been able to communicate regarding disruptions more quickly. Instead of hoping to restock, manufacturers might have been able to ramp up production in anticipation of a possible shutdown. Now, the threat of another wave of the pandemic feels almost inevitable.

USING DATA TO IMPROVE DEMAND FORECASTING IS ALSO CRITICAL TO ACCOMMODATE SWELLING DEMAND ACROSS NON-TRADITIONAL CHANNELS

COVID-19 highlighted non-traditional shopping channels. Even today, consumers remain skeptical of whether it is safe to venture to their favorite brick-and-mortar stores, and e-commerce shopping continues to grow. Walmart is on the verge of unveiling an innovative competitor to Amazon Prime in the form of Walmart+. And, Amazon is continuing to reshape its return policies in response to the pandemic. Meanwhile, the industry is headed toward a series of bullwhip effects. This term describes the small fluctuations in COVID-19 hotspots that contribute to major disruptions. Every supply chain on the planet is working to try to mitigate losses and make up for the disruptions caused over the past few months. With that in mind, the application of freight data holds an additional value. Using data, supply chains could better plan replenishment orders, avoid congestion and prevent further disruption.

DATA ENABLES TRANSPORTATION OPTIMIZATION

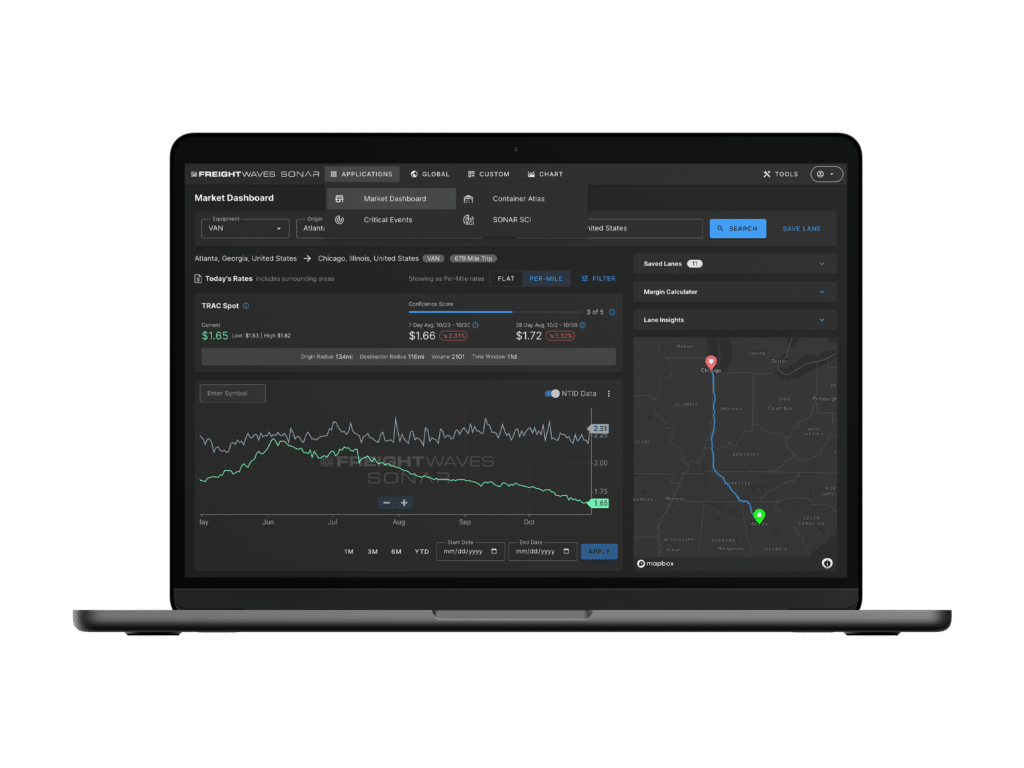

Using freight data to manage logistics helps to increase efficiency among drivers, loading, unloading, route optimization, use of multimodal transport, and much more. In the modern world, nearly every supply chain is incredibly complex. For example, the consideration of the full scale and spectrum of available modes is essential to ensure the best rates and service level for freight. It is not enough to simply ship with the fastest or the cheapest carrier. Instead, modern carriers and logistics service providers need to offer the best service possible. Consider this. Many millennials are willing to pay a premium for service levels on their shipments. This premium could help pay for technology upgrades to better enable optimization and reduce delays – as well as promote efficiencies in replenishment.

DATA ALSO AFFECTS INVENTORY MANAGEMENT

While on the topic of freight data and its use in meeting just-in-time fulfillment, it is important to consider the lean conundrum. The lean conundrum is the problem that was created by a sudden surge in demand and extremely lean inventory management strategies. Organizations have grown complacent with lean inventory, and lean inventory helps to reduce carrying costs and improves shipment lifecycles. Unfortunately, that is not a reality for responding to a major disruptive event. So, what can companies do? The answer is simple; get the data before, during and after a disruption occurs.

REAP THE REWARDS OF FREIGHT DATA WITH THE RIGHT PLATFORM

Companies must apply freight data to understand all of the influences that impact their freight. Consumers’ shopping is up, and no one knows when it is going to decline. The only way to ensure available capacity and keep freight spend under control during disruption lies in collecting, analyzing and applying freight data to make informed decisions that proactively prevent uncontrolled logistics spend creep. Get access to the latest freight data to enable disruption-proof supply chain management strategies by requesting a demo of FreightWaves SONAR today.