For manufacturers, prioritizing a seamless order fulfillment experience is key to driving repeat business. In these times where customer expectations are higher than ever, efficient order fulfillment is no longer a luxury — it’s a critical competitive advantage.

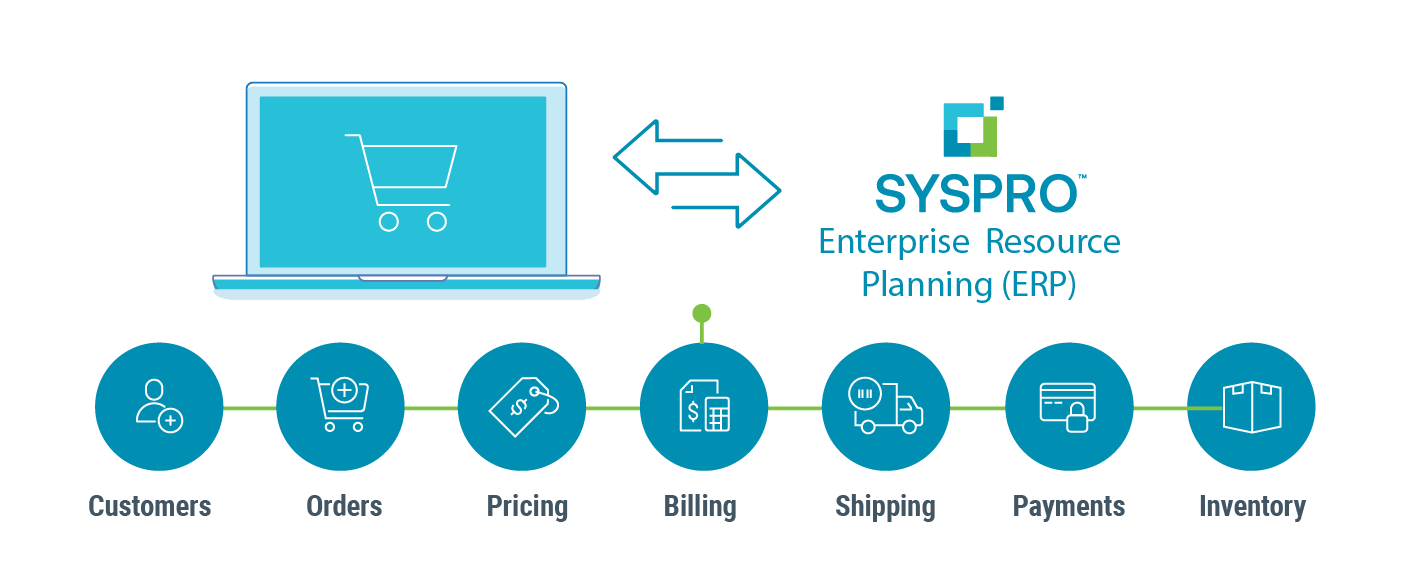

However, to meet these expectations, manufacturers need to ensure a smooth flow of information between their eCommerce platform and core business functions such as inventory, finance, production, shipping, and logistics.

Let’s explore how manufacturing businesses can optimize their fulfillment processes for success.

What is order fulfillment?

Order fulfillment refers to the process of receiving, processing, and delivering an order to a customer. This process involves multiple stages, including receiving the order, sourcing parts and components, manufacturing or assembling the final product, picking and packing, shipping, and tracking the shipment to ensure successful delivery.

How does this process work?

The order fulfillment process involves several steps to ensure that customer orders are processed, fulfilled, and delivered efficiently.

Throughout the order fulfillment process, inventory management, production planning, shipping, and communication with customers are critical to ensuring accurate and timely deliveries. Modern technologies such as ERP systems and warehouse management systems play key roles in streamlining the order fulfillment process for manufacturers.

- Order placement: The process begins when a customer places an order, either through an online store, over the phone, or through other sales channels.

- Order processing: Once the order is received, it is entered into the system for processing. This step involves verifying the order details, checking product availability, and confirming payment.

- Picking: After processing, the order moves to the picking stage. Warehouse staff or automated systems pick the items from the inventory based on the order details. If the order requires production or assemble, it moves to the production planning function.

- Packing: Once the items are picked, they are packed into shipping containers or packages.

- Shipping and delivery: After packing, the order is ready for shipment and delivery. Depending on the shipping method, customers may receive tracking information to monitor the delivery status.

- Order confirmation: Once the order is delivered, the system generates an order confirmation or delivery notification to inform the customer that their order has been successfully fulfilled.

- Post-delivery follow-up: Some businesses also include post-delivery follow-up steps, such as customer feedback requests, return or exchange processes, and ongoing customer support.

The role of ERP in efficient order fulfillment for manufacturers

ERP systems can significantly improve order fulfillment for manufacturers in several ways. ERP systems can seamlessly integrate with eCommerce platforms to transfer order details, ensuring a smooth experience for both manufacturers and their customers.

- Eradicates manual data entry: Your ERP system is the central repository of all information, including product details, inventory levels, customer data, and shipping instructions. This eliminates the need for manual data entry across different systems, reducing errors and streamlining the order fulfillment process.

- Visibility into sales, finances, and inventory levels: You can gain real-time visibility into inventory levels, production schedules, and order status across the entire fulfillment chain. This allows for proactive decision-making and faster response times to any potential delays.

- Forecasting trends for production planning: ERP integrates with sales data to generate accurate demand forecasts. This helps manufacturers maintain optimal inventory levels, minimizing stockouts and the need for backorders, which can cause delays.

- Ease of lot & serial tracking: For manufacturers dealing with serialized or perishable items, ERP can track them through the entire fulfillment process, ensuring quality control and compliance with regulations.

- Enhances customer experience: Customers can access real-time tracking information through the online storefront of manufacturers, providing transparency and reducing order inquiries. It also serves as a channel to communicate with customers regarding any concerns about their orders.

- Reduces shipping errors: The automation and improved data visibility within ERP minimizes picking and shipping errors, leading to faster and more reliable delivery times.

- Improves communication across different departments: ERP facilitates communication between departments, allowing for smoother order fulfillment and faster response to customer inquiries.

Overall, by implementing an ERP system, manufacturers can streamline their order fulfillment processes, improve efficiency, and deliver a superior customer experience, ultimately leading to increased sales and a better customer experience.

If you want to learn about how ERP and eCommerce platforms work together, you can download our Digital Commerce infographic.

1 thought on “eCommerce for Manufacturers: How an ERP can help order fulfillment”

This blog post beautifully highlights the transformative power of ERP software in enhancing order fulfillment processes. The comprehensive insights provided here showcase how an ERP’s streamlined approach can lead to greater efficiency, accuracy, and customer satisfaction. It’s truly inspiring to see how businesses can leverage technology to optimize their operations and ensure that every customer’s order is processed seamlessly. This article has certainly deepened my understanding of the benefits an ERP can bring to order fulfillment, and I’m excited to see more companies embrace this solution to create smoother and more delightful customer experiences.