Last summer, Joel TeBrake, overseeing the maintenance side of his family-owned and Minnesota-headquartered Truck Transport small fleet, was looking ahead to a project of whose value he’d become convinced.

On much of its company-owned equipment, Truck Transport was moving to air disc brakes instead of conventional drums. The principal reason? “Serviceability,” TeBrake said. “We’re seeing a lot of advantage out of that. The service part of it is next to nothing, and they last quite a long time.”

They’re generally “a little lighter, too,” he added, another plus in an operation that pulls mostly double drop step decks and RGNs that can max out on weight.

Those aren’t the only advantages that come with disc brakes. “They tend not to get as hot as fast, and they’re probably better in terms of stopping power,” said owner-operator and longtime diesel mechanic Martin Herman, based out of Evanston, Wyoming.

TeBrake’s move is part of a trend that’s really accelerated in recent years, according to Bendix, a leading brake manufacturer, as truck makers and their customers have become convinced that disc-brake technology is long since ready for prime time in trucking.

Peterbilt was the first to make air disc standard, in the steer position in 2012, with Kenworth shortly following suit, said Nicole Oreskovic, a Bendix senior director for marketing/product planning. “Navistar went all-wheel ADB in the summer of 2018,” she added, and today “three of the big four” are all-wheel air disc, standard. “The cost premium associated with the technology has really gone down considerably” over that time period, too, while maintenance and other advantages remain.

Brian Bent, Idaho-based independent owner-operator of Mountain West Transport, has recently shopped around for a potential replacement trailer for his 48-foot spread-axle flatbed, outfitted with drum brakes.

With what he was seeing, he figured as little as $60 an axle in terms of initial investment premium for trailer discs over drums, though that premium will vary dependent on the operation. “I want a trailer with disc brakes” to match those on his 2015 Peterbilt 579, Bent added about his principal motivation for trading his flatbed. “You can really feel the difference in the braking” between tractor and trailer as it is, he added.

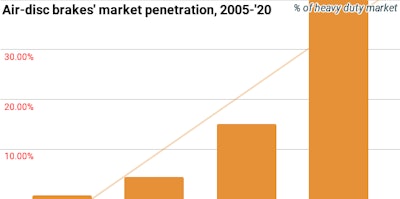

Bendix Product Director for air brakes Keith McComsey laid out the numbers you see in the chart here, his best estimate for heavy-duty market penetration in five-year increments starting with less than a single percent of all foundation brakes in North America in 2005 to about 40% today and rising fast. Added Nicole Oreskovic: “We’ve followed Europe a bit,” where disc brakes in heavy trucks have “been standard since the early 1990s. I would say that, globally, the standard foundation brake is an air-disc brake” in heavy duty trucks.

Bendix Product Director for air brakes Keith McComsey laid out the numbers you see in the chart here, his best estimate for heavy-duty market penetration in five-year increments starting with less than a single percent of all foundation brakes in North America in 2005 to about 40% today and rising fast. Added Nicole Oreskovic: “We’ve followed Europe a bit,” where disc brakes in heavy trucks have “been standard since the early 1990s. I would say that, globally, the standard foundation brake is an air-disc brake” in heavy duty trucks.

“Drums have a tendency to fade,” or lose stopping power, “when they get hot,” said McComsey. “The drum heats up and expands away from the friction material.” The result: “Reduced torque on the wheel end.”

With disc, that doesn’t happen. “No matter how hot it gets,” said McComsey, they’ll “always provide that stopping power.”

Oklahoma-based small fleet owner Greg Anderson’s first-ever-owned tractor with all air disc brakes is a 2019 Kenworth W900L he bought used in recent history from an owner-operator. He tested McComsey's notion himself, of a fashion, he said, coming down Cabbage Hill “pretty quick” on I-84 in Oregon. The discs “impressed me.” He’s recently shifted his equipment investment strategy from long-term ownership with a close focus on maintaining for longevity to quicker trade cycles to keep newer-model emissions-heavy equipment under warranty.

“When I get new trucks now,” he added, “they will have discs on them.”

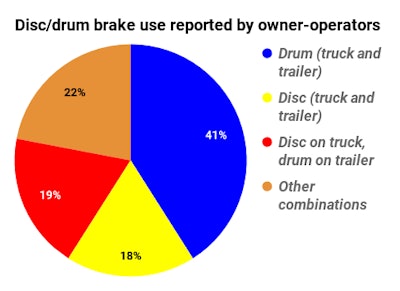

Owner-operators in Overdrive’s audience show rates of disc-brake adoption roughly equivalent to Bendix estimates shown in the prior chart, if not more prevalent, given the variety of combinations represented in the “other combinations” slice of the pie: Disc on truck, trailer varies (6%) and a combination of both on truck and trailer (5%); drum on truck, disc on trailer (4%); and others.OverdriveOnline.com poll -- early 2021

Owner-operators in Overdrive’s audience show rates of disc-brake adoption roughly equivalent to Bendix estimates shown in the prior chart, if not more prevalent, given the variety of combinations represented in the “other combinations” slice of the pie: Disc on truck, trailer varies (6%) and a combination of both on truck and trailer (5%); drum on truck, disc on trailer (4%); and others.OverdriveOnline.com poll -- early 2021

Trucker Scott Reed, now the pilot behind the wheel of Anderson’s 2019, has been impressed, too, pulling liquid bulk tank most often. Over years as vehicle traffic on U.S. highways and interstates has steadily increased without a commensurate expansion of available lanes, and as CB usage has fallen off among some in the trucking community, encountering unexpected slowdowns on high-speed roads has gotten to be a more regular feature of hauling. Since Reed’s taken the reins of the W900L several months back, “I’ve had some hairpin-type situations happen on the road already,” he said. “I’ve never smoked them, I’ve never even smelled them. I can’t complain about them. If I ever bought a truck I’d buy one with disc brakes or maybe switch them out,” though that might not always a sensible option from a basic return-on-investment calculation, given the work involved.

The image is from a video demo of air disc stopping distance advantages over conventional drums with a hard stop from 70 mph in four otherwise similarly-equipped tractor-trailers. With ADBs on more and more wheel positions, stopping distances get progressively better. Bendix, who produced the video in 2017, also offers customers a value calculator at this link into which a truck owner can punch his/her own numbers to estimate potential costs and benefits of ADB adoption. The Haldex company also offers such an online calculator at this link.

The image is from a video demo of air disc stopping distance advantages over conventional drums with a hard stop from 70 mph in four otherwise similarly-equipped tractor-trailers. With ADBs on more and more wheel positions, stopping distances get progressively better. Bendix, who produced the video in 2017, also offers customers a value calculator at this link into which a truck owner can punch his/her own numbers to estimate potential costs and benefits of ADB adoption. The Haldex company also offers such an online calculator at this link.

Scott Reed, pictured here with the disc-brake-outfitted 2019 W900L he pulls with for Greg Anderson's AK Trucking (leased to Woof Trucking), had to come to a pretty quick slowdown "on Jellico one morning" recently, he said, referencing one of the towns and mountains in East Tennessee I-75 crosses. He was "on the S curve starting down on the Southbound side – it was foggy, couldn’t see much of anything, and nobody said anything about it over the CB. I had no problem going from about 65 to 20" in very short order "and still had good pressure."Photo by Todd Dills

Scott Reed, pictured here with the disc-brake-outfitted 2019 W900L he pulls with for Greg Anderson's AK Trucking (leased to Woof Trucking), had to come to a pretty quick slowdown "on Jellico one morning" recently, he said, referencing one of the towns and mountains in East Tennessee I-75 crosses. He was "on the S curve starting down on the Southbound side – it was foggy, couldn’t see much of anything, and nobody said anything about it over the CB. I had no problem going from about 65 to 20" in very short order "and still had good pressure."Photo by Todd Dills

It does happen often enough, though, and for an owner-operator planning to hold on to the truck for longer periods of time, the long-term maintenance value of an air disc brake “can multiply," said Oreskovic. “Look at the savings [when comparing a change in] a drum shoe versus a disc brake pad,” plus the latter’s extended intervals.

That’s one element that drove TeBrake’s decision to begin converting the company units in his mostly owner-operator fleet, said Joel’s brother and fellow small fleet owner, Jay TeBrake. “Joel pulled the wheels off a 650,000-mile truck and pulled the disc pads out. A new pad is about three-quarters of an inch thick. These had just a quarter-inch of wear on them.”

Beware misconceptions, at once, that air disc brakes are “bulletproof,” said Bendix’s McComsey. “Every brake needs some level of routine maintenance, and the air-disc brake is no different.” Thankfully with discs, he said, it “doesn’t take as long.”

A good resource for basic maintenance considerations around disc brakes is Overdrive sister publication CCJ's long-running "Air Brake Book," whose 10th edition added a detailed chapter on air disc market penetration and ways to the cost-benefit calculation when examining potential for a switch. Download the book via the form at this link.

A good resource for basic maintenance considerations around disc brakes is Overdrive sister publication CCJ's long-running "Air Brake Book," whose 10th edition added a detailed chapter on air disc market penetration and ways to the cost-benefit calculation when examining potential for a switch. Download the book via the form at this link.

Also be skeptical of longer-life claims of non-OE-made friction for any braking system. “Some that tout longer-life friction” are accomplishing that by “adding more metal, which could become a detriment to the rotor” itself, McComsey said, “creating stress cracks” over time.

That could be a brake violation during a routine roadside inspection, and “you’ll need to replace that rotor,” he added.

For highway trucks, all of these things are true, but one area where drums continue to be a preferred option would be in heavy off-road usage. Owner-operator Martin Herman, who hauls principally for the Wyoming-based Dustbusters company, supplying de-icers and stabilizing liquids used on unpaved roads, put it this way: “They can catch a lot of garbage,” given a fairly open design. “Dirt, mud, salt, other road debris can get into the working parts.” With that, “there can be more wear.”

Oreskovic pointed out dust shields and pad shields offered “to keep it from getting in and degrading the pad,” but generally described the air-disc brake as an “on-highway brake with some off-road applications.”

Real issues occur particularly in operations with heavy mud that gets caked on the caliper or rotor. “One of the bigger things we’ve seen is rotor veins that get caked with mud,” said McComsey. “They’re designed to pull air in and heat out.”

McComsey echoed Herman’s contention then about wear. “The more heat the rotor absorbs,” McComsey said, “the more wear long-term.”