Companies are trying to get packages into the hands of customers faster, but so-called last-mile delivery can be costly.

March 18, 2020

The recent rise of e-commerce generally – and the powerful influence of e-commerce leader Amazon specifically – changes the rules in freight asset management. A case in point is last-mile delivery, an area where IoT (Internet of Things) data may not yet be fully tapped.

The Amazon Prime push for two-day – and even same-day – delivery has altered perceptions of what’s possible in shipping. It also challenges companies of all kinds to employ IoT and other technologies to boost logistics skill sets and meet customers’ new expectations.

Now more than ever, the goal is to get deliveries out of warehouses, off trucks and into customer’s hands – or, at least, onto their doorsteps.

This quest places attention on another “last mile”: the final stretch in the IoT data chain, where business users cull IoT sensor data to make decisions on the most efficient means to move freight to its destination.

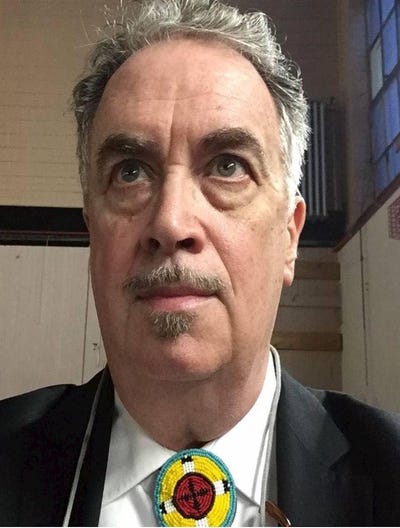

“Amazon is putting a lot of pressure on the industry, and everybody is reacting,” said John Richardson, vice president of supply chain analytics at third-party logistics provider Transportation Insight LLC.

But he said, there are risks in trying to replicate Amazon’s one-day drive.

“It always comes back to profitability. People think they need one- or two-day service and are reacting to that. But everyone will come to ask if they can have one- or two-day services and profitability,” Richardson said.

Last-Mile Delivery Service: Right Place, Right Time

For Richardson, last-mile delivery optimization is primarily about putting the right product in the right place at the right time.

“A lot of optimization advances in the last 20 years have been focused more on cost and less about service. Now you see service get more play, and the inventory optimization piece is key,” he said.

How close you can be to your customer is the important thing, he emphasized. “That is where last-mile optimization comes in.”

Location data is vital to last-mile logistics. And, with the advent of IoT tracking devices, that data is no longer solely the province of the freight carrier.

“With some of the new technology, you can put trackers on the products, and not be dependent on the carrier for location information,” Richardson said. “This is going to drive more real-time types of decisions by business users.”

Asset Tracking: Follow the Data

The bring-your-own-devices trend is part of an asset tracking software market expected to be worth $11 billion a year by 2023, according to Market Research Future.

But creating state-of-the-art asset tracking systems has proved difficult for early IoT implementers, who needed to connect many moving parts to improve last-mile delivery. This has led some vendors to forge alliances to create end-to-end packages for asset management.

A full “data-to-outcome” package that can better track and understand asset locations is the goal of a partnership among telecommunications mainstay Verizon, business intelligence software maker Domo and Amazon Web Services, the cloud computing arm of Amazon. This asset monitoring system moves IoT data collected by Verizon LTE sensors to a Cat-M1 network.

This is published to AWS IoT Core services via the Verizon ThingSpace platform. AWS IoT Core includes a built-in rules engine that can filter and route data through to the Domo IoT analytics platform.

That puts IoT data analytics in the hands of business decision-makers, according to the partnering companies. This can be daunting for users trying to combine data from IoT endpoints with real-time weather, traffic or other data that can affect last-mile delivery.

Without such pre-packaging, “people have to put a lot of technology Lego blocks together themselves, which adds more complexity and v more importantly – more time to realizing their desired outcomes,” said Shamik Basu, director of IoT products, Verizon Wireless.

Making IoT device data available for decisions has required a lot of user effort, agrees Jay Heglar, chief business officer, Domo.

This has even created a “last-mile problem” of a different type, he says. As companies try to deliver useful data analytics to employees that must ensure the final leg of a delivery is completed efficiently. Without useful analytic dashboards, he said, people tracking assets have no way to effectively consume the IoT data.

Last-Mile Complexity Grows

Today, a range of innovative means are under consideration for last-mile delivery service. These range from scooters to drones. Additionally, last-mile delivery service now includes an array of heavyweights from Walmart and Amazon to startup companies, such as Boxbot and Spark Delivery. At the same time, various small companies are stepping up to the last-mile challenge.

A trend toward omnichannel retail distribution has made last-mile delivery even more complex, according to Paul Myerson, instructor of management at Monmouth University, and author of “Lean Demand-Driven Procurement.”

“Besides traditional forms of delivery, companies have been exploring air and land drone delivery and lockers in pre-designated, urban or suburban locations available for customer pickup, such as at convenience stores,” he said.

Other new practices include handling online order pickup, shipping and returns at brick-and-mortar stores. These also add to the number of variables that make up logistics decisions today, he continued.

“People are looking for creative ways to extend their reach,” said Ken Fleming, president and chief sales officer at transportation management firm Logistyx Technology. “This could be a grocery chain that is in everyone’s neighborhood or could even be the local ‘pizza guy.”

Companies are getting creative in how they get things done. In new scenarios, “the mobile device becomes the ‘thing’ in the Internet of Things,” Fleming said. “It’s IoT that is making it possible.”

What are first steps for implementors looking to improve the last mile of logistics? Fleming said that companies sometimes overlook planning, but in fact preparation for “the last mile should be the first thing you think about.”

“IoT is the enabler, but lack of planning is sometimes astonishing,” Fleming said.

New machine learning based predictive analytics tools will gain in importance as companies realize last-mile decisions must be accomplished more quickly, emphasizes Transportation Insight’s Richardson.

“IoT data itself is not as important as what you do with it,” he said, “Don’t make a lot of investments in something that is not going to be actionable for the business.”

When it comes to last-mile logistics, “you have to be able to do things very quickly,” he said. Improved machine learning implementations can help. “You need valid data, but you can’t take a lot of time for data cleansing.”

Knowing there are last-mile traffic delays is one thing – knowing what to do to reroute deliveries is another. As IoT asset management technology improves, more efficient rerouting will be more widely available, Richardson indicated.

About the Author(s)

You May Also Like

.png?width=300&auto=webp&quality=80&disable=upscale)

.png?width=300&auto=webp&quality=80&disable=upscale)