Fulfilment Case Study: Barcode Tech Boosts Auto Handling of Personalised Mail

21st January 2020

In this case study fulfilment specialist Mail Handling International (MHI) says that Datalogic barcode scanning technology has enabled it to dramatically enhance speed and accuracy for the automatic enclosure of personalised letters from its Bristol based mail fulfilment centre. Combining Datalogic Matrix 300N barcode readers with software provided by Scansys, MHI can match and insert personalised letters into their corresponding envelopes at a rate of 4.16 items per second.

Alex Lawson, Director at MHI explains how the growth of one client’s requirement for personalised direct mail drove their investment in a Datalogic scanning solution: “When we first engaged with this particular customer, we were handling around 50 items of mail per day for them, with letters fulfilled into envelopes by hand. In under three years, that volume has scaled rapidly to over 100,000 items per day. In order to support this significant increase in demand, and ensure 100% accuracy for the customer, we needed to invest in new machinery to automate the enclosure of each mailer.”

MHI’s existing enclosure machine could insert letters into envelopes at a rate of around 4,000 to 5,000 per hour, a rate that fell short of the target. This initial challenge was quickly overcome by sourcing an insertion machine that could run at around 20,000 enclosures per hour but there was an additional level of complexity that had to be taken into consideration. At the point of insertion, MHI needed to ensure that the correct letter was inserted into the matching envelope.

“The body of each letter is personalised to the recipient at a number of different points,” explains Lawson. “Then to increase that element of personalisation, rather than insert each letter into envelope with a window displaying the address, each envelope is printed with the recipient’s address in a way that makes it look as though it’s been written by hand. Getting this matching process correct is vital to the success of the client’s mailer, so finding a solution that could ensure 100% matching accuracy at these volumes and speed was critically important.”

After working successfully on other scanning and data capture projects within the wider organisation, MHI approached data capture and vision system specialist ScanSys to identify the best solution for their matching application requirements.

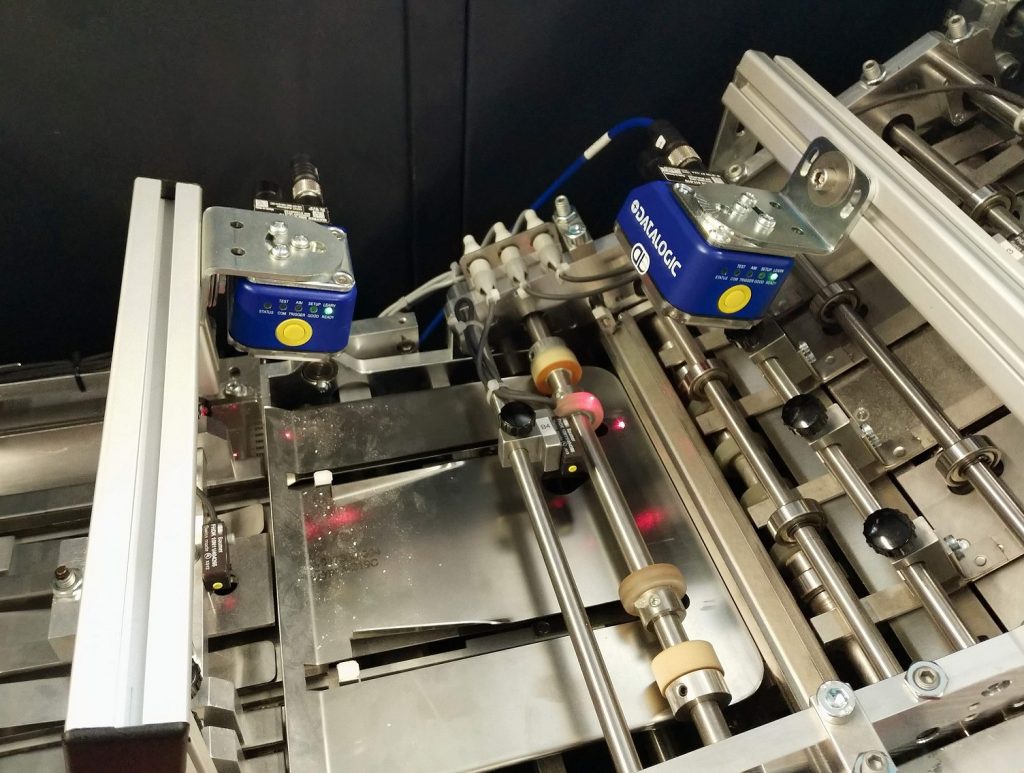

ScanSys installed two Datalogic Matrix 300N barcode readers on the upgraded mail insertion machine. The compact design of the Datalogic product meant that each of these devices could be positioned exactly at the point of insertion. Just prior to the letter being inserted into the envelope, the Matrix device captures a 2D mail mark barcode on the envelope. At the same time and in the same reading phase a 2D code on the letter is also captured.

In the two months following installation, MHI matched and enclosed 2.6 million envelopes using the system. On average, 4.16 matches are verified every second. “The Datalogic and ScanSys solution has already massively improved our productivity and given us a lot of confidence in the matching scenario,” states Lawson. Prior to the automated system, MHI’s staff were only able to carry out intermittent checks on the accuracy of the matches. If a non-match was found, a considerable amount of time would have to be spent going through each enclosed envelope to identify where the process went out of sync.

“On average we were sampling at a cadence of around every 500 items,” continues Lawson. “If the non-match was discovered at number 3 of the 500, then not only would it take a long time to identify the original inflection point, but it would also mean that every letter from that point would have to be reprinted and re-enclosed. Together the Datalogic readers and the ScanSys control system enable us to check and verify each letter to guarantee an exact match every time. The whole process happens within a fraction of a second and any non-matches can be quickly rectified.”